y0732/02 GPM Big Scale adjustable 3 shoe clutch with tuning clutch bell for HPI models, 1 pce.

Product information "y0732/02 GPM Big Scale adjustable 3 shoe clutch with tuning clutch bell for HPI models, 1 pce."

Nitriding hardened clutch bell: 40,50 EUR

complete price:.......................150,40 EUR

Adjustable 3-shoe clutch for:

Zenoah / Chung Yang / HPI - Fuelie / Smartech PT and many other engines.

The delivery content:

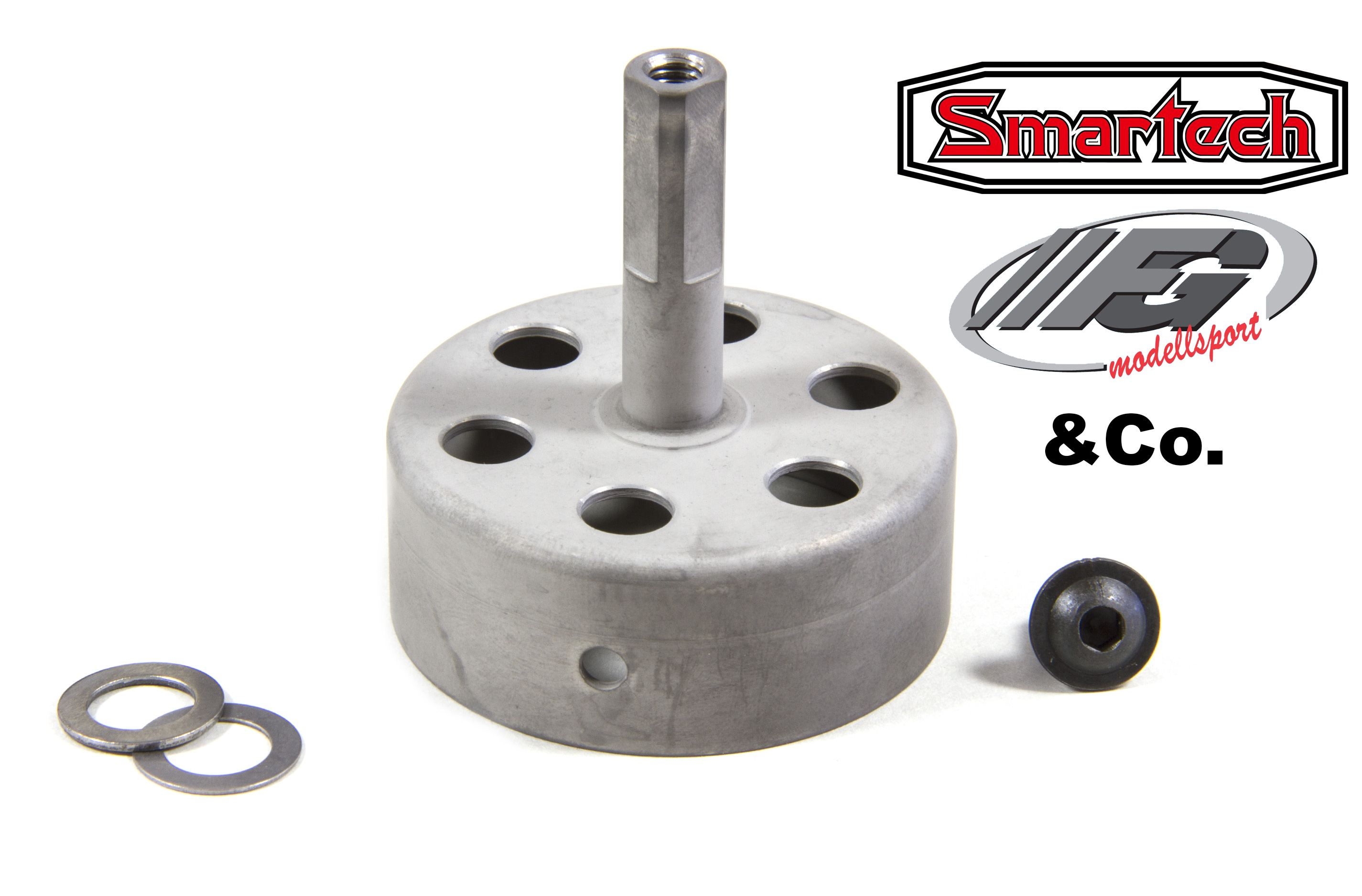

- y0730 GPM Big Scale-Cross adjustable 3 shoe clutch, 1 pce.

- y0729 Gas-nitrited tuning clutch bell for HPI Baja, 1 pce.

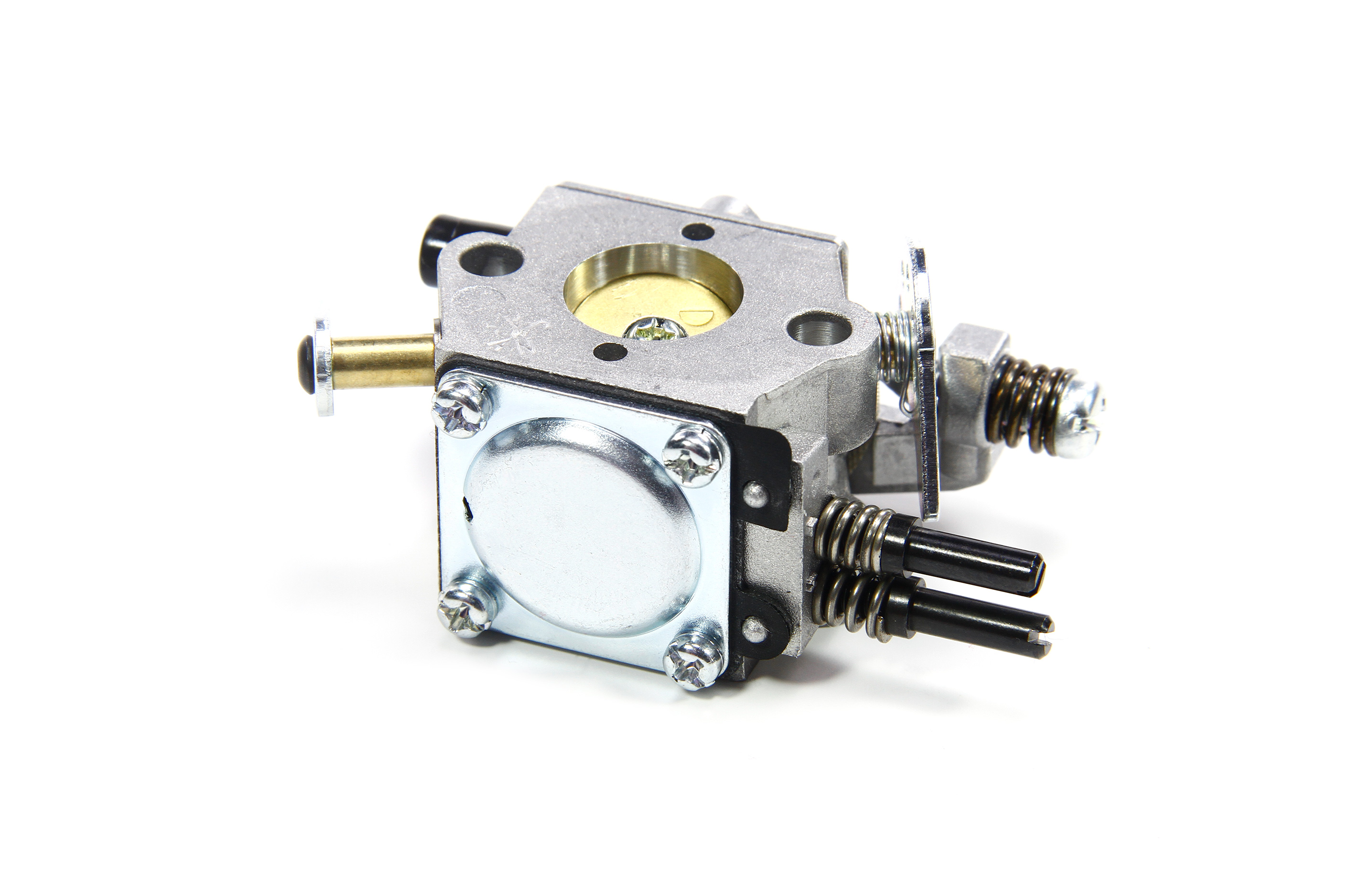

The Gas-nitrited tuning clutch bell:

Gas-nitrited tuning clutch bell machined from high grade steel with a hole for easy clutch adjustment. Special vents remove dirt and clutch lining debris automatically, preventing it from accumulating in the clutch bell and causing premature wear to clutch bell and linings. They aid in cooling of the clutch bell as well.

The clutch bell features a significantly reinforced wearing surface and face which guarantees dimensional stability even under high loads! The shaft is a tiny bit longer than stock (about 0.2 mm) to prevent the bearings from binding.

Since this clutch bell is single-piece machined from bar stock there is no weld bead on the inside of the face plate. The gained space allows now to use the adjustable GPM Big Scale-Cross clutch.

Suitable for genuine slot drive HPI pinions.

Comes with bolts and spring washers included.

The GPM-Big Scale clutch:

Suitable for racing and for the ambitious hobbyist driver. Unlike the stock clutch, the installed GPM-Big Scale clutch can be adjusted by turning one single screw. A 2.5 mm allen key wrench is required for this application.

Therefore it is possible to precisely adjust the clutch engagement depending on track characteristics.

Handling instructions for three-shoe clutches y0730 GPM Big Scale Cross and y0731 GPM Big Scale Race

Installation:

The GPM Big Scale clutch will be bolted to the crankshaft using the supplied CSH-screw.

It should be noted that the use of thread locking compound on that screw is neither necessary nor recommended!

Removal:

Remove the CSH-screw with a 4mm Allen wrench; then insert a suitable M8 bolt and remove the clutch from the crankcase cone by tightening that bolt.

Hole for adjustment:

For clutch adjustment without removing the clutch bell a 4 4.5 mm hole must be drilled into the clutch bell for access to the adjustment screw. Placement of the hole depends on clutch bell dimensions and car; so you have to make your own measurements for the placement of the hole.

It is important that the drilled hole is thoroughly deburred (at least on the inside of the clutch bell) to prevent excessive clutch pad wear.

Breaking in:

A new clutch or shoes fitted with new pad should always be broken in. Therefore the clutch engagement speed should not be too high for the first tank of fuel. This gives the lining the possibility to adjust to the clutch bell without glazing.

The only difference between two clutches is the clutch spring rate, which provides the optimal range for clutch engagement depending on the application.

The three available versions of clutch springs provide adjustability within the following RPM ranges:

Silver springs 1.3 mm y0730/05 (standard on Big Scale Cross): 5,000 9,500 RPM

Gold springs y0730/06 1.4 mm (standard on Big Scale Race): 6,500-11,500 rpm

Adjustment:

Adjustment of the clutch engagement speed is done by one single screw using a 2.5 mm Allen wrench.

Turning the screw in increases the stall speed, backing it out will lower the stall speed. The adjusting screw is thread locked to keep the setting. Should you realize that the screw can be turned too easily please re-apply medium strength thread locking compound.

Finding the best clutch engagement speed:

The best clutch engagement speed should be found while driving on the track, it depends on engine characteristic, track layout, track surface and driving style.

It is recommended to start with the lowest setting (which means the set screw just touching the adjustment cam) and gradually turning the adjusting screw in while doing test runs after every adjustment.

If you feel that you have exceeded your best engagement speed (clutch will slip too much), back the screw out for a little bit to avoid excessive wear or glazing of the pads.

Attention: You must use adhesive y0743 Clutch-Safe when replacing clutch pads!

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Accessories / Spare parts

Average rating of 0 out of 5 stars

Content: 10 Gramm (€495.00* / 1000 Gramm)

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Customers also bought

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Similar products

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Customers also viewed

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars

Average rating of 0 out of 5 stars