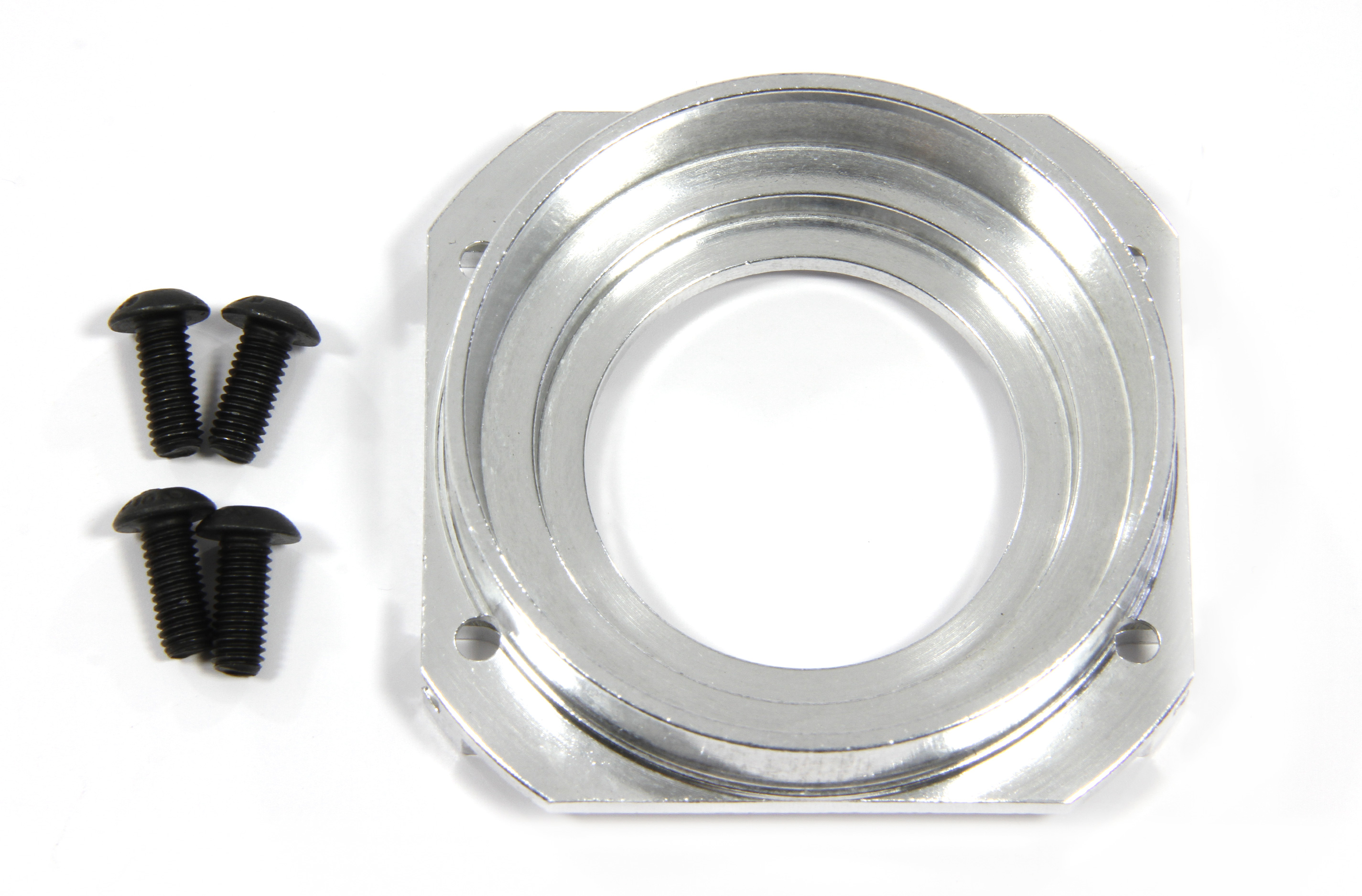

y0730/17 Clutch housing

rc-car-online

€22.90

Available

Product number:

y0730_17

EAN:

4058575036357

Product information "y0730/17 Clutch housing"

Genuine GPM spare/option part.

Part no. 17 for GPM Big-Scale clutch.

Content:

Part no. 17 for GPM Big-Scale clutch.

| y0730 | y0731 |

Content:

- 1 piece

Login

No reviews found. Share your insights with others.