UFRC Ghost Rabbit GR1 4WD 1:5 Brushless Buggy 8S, RTR Version

€2,750.00

% €2,990.00 (8.03% saved)

Zubehör

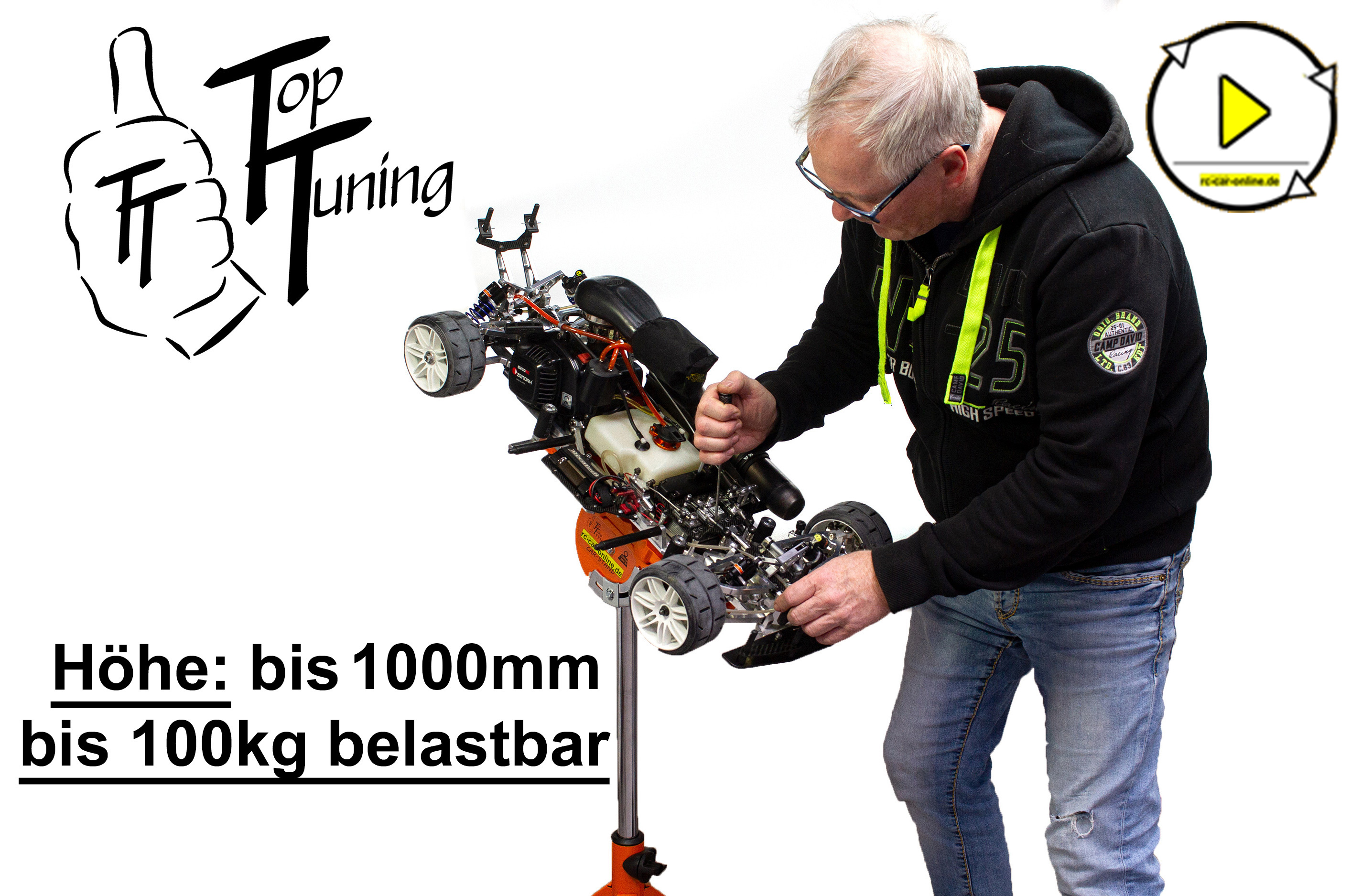

Ideal work stand with extra wide tripod up to 100 kg. load capacity with excellent stability, even on uneven (!) urface.Specially made support mechanism, individually adjustable width from 115 mm to 375 mm for most RC cars from 1/10 to 1/5 scale. incline from 0 to 90° Quickly folded and loaded For easy storage, as well as for transport completely foldable! (Carrying bag available!)Height adjustment of the support from 635 mm to 1000 mm and inclination from 0-90° Length of the support surface 386 mm Bis zu 100Kg belastbar! Support mechanism continuosly adjustable in width Due to various adjustment options, the Top Tuning CAR STAND offers the optimal possibilities for making adjustments or maintenance work on the RC car. The load capacity and stability are beyond doubt with a load limit of 100 kg and the extremely stable tripod. The up to 90 ° adjustable slant shows your RC car at events and presentations, as well as in your assembly room to its best advantage! 6.5 kg. weight Pivoting bracket Height adjustable from 69 to 104 cm Basic frame is made of steel, painted or chromed Car bracket is made of aluminum and stainless steel A tool holder TT1030/01 is also available as an accessory in our shop selection.

Genuine Top Tuning spare/option part.For secure transport and storage of LiPo batteries. For batteries up to approx. 175 x 75 x 70 mm.Contents:1 piece

The XXL version is especially made for the Losi 5ive-T, Mini 5ive WRC, Desert Buggy XL; Arrma Outcast/Kraton; Axial Honcho, Traxxas X-Max/XRT; UFRC GR1/Big Bully. Of course, other 1/5 and 1/6 large scale cars will fit into this bag as well; however, in this case the XXL bag gives you plenty of room for additional accessories. Made from extremely durable fabric, easily washable; with wrap-around shoulder belts and zipper closure. No dirt in the car boot! Dimensions: Length: 100 cmWidth: 57 cmHeight: 39 cm

Product information "UFRC Ghost Rabbit GR1 4WD 1:5 Brushless Buggy 8S, RTR Version"

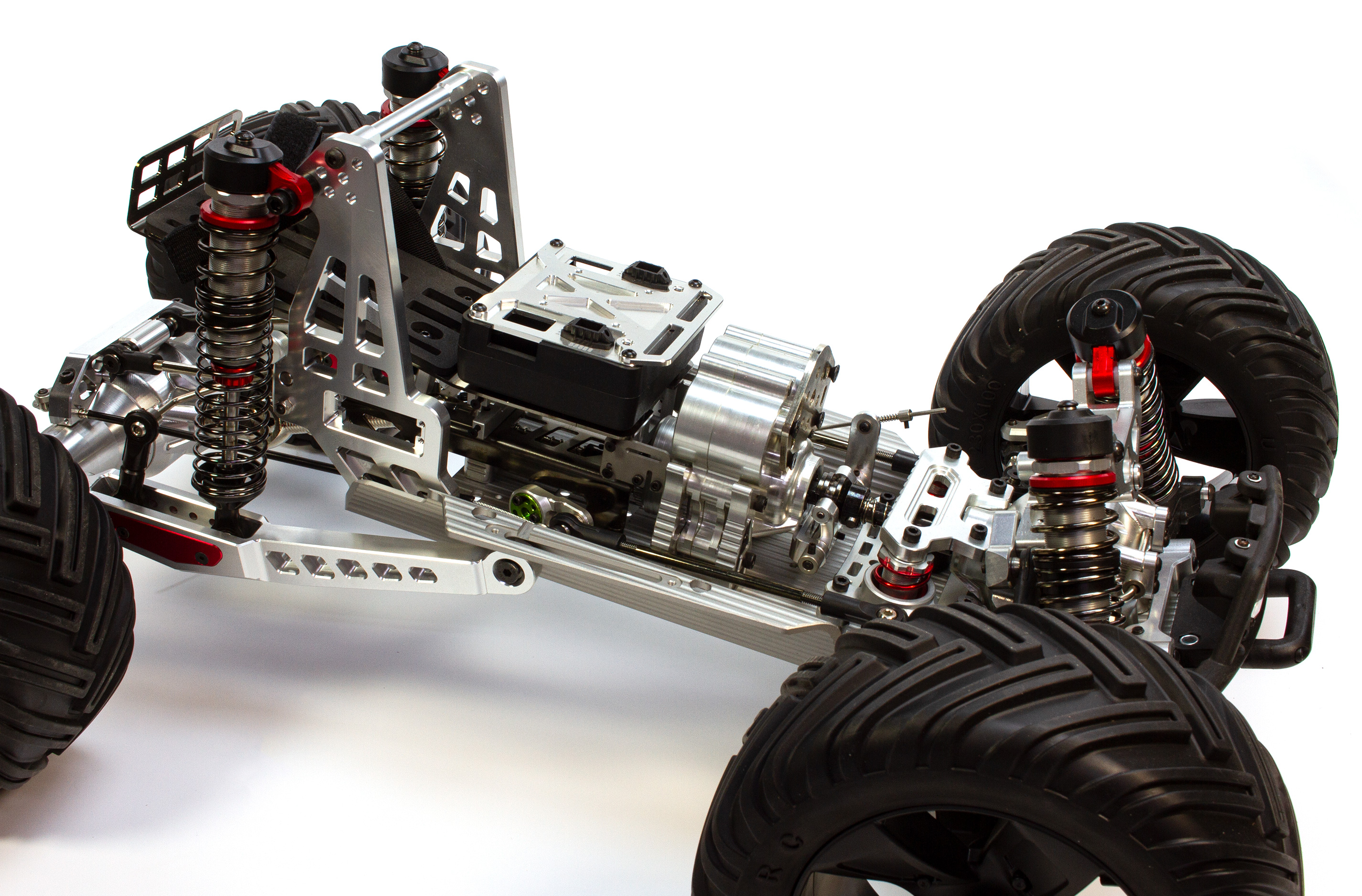

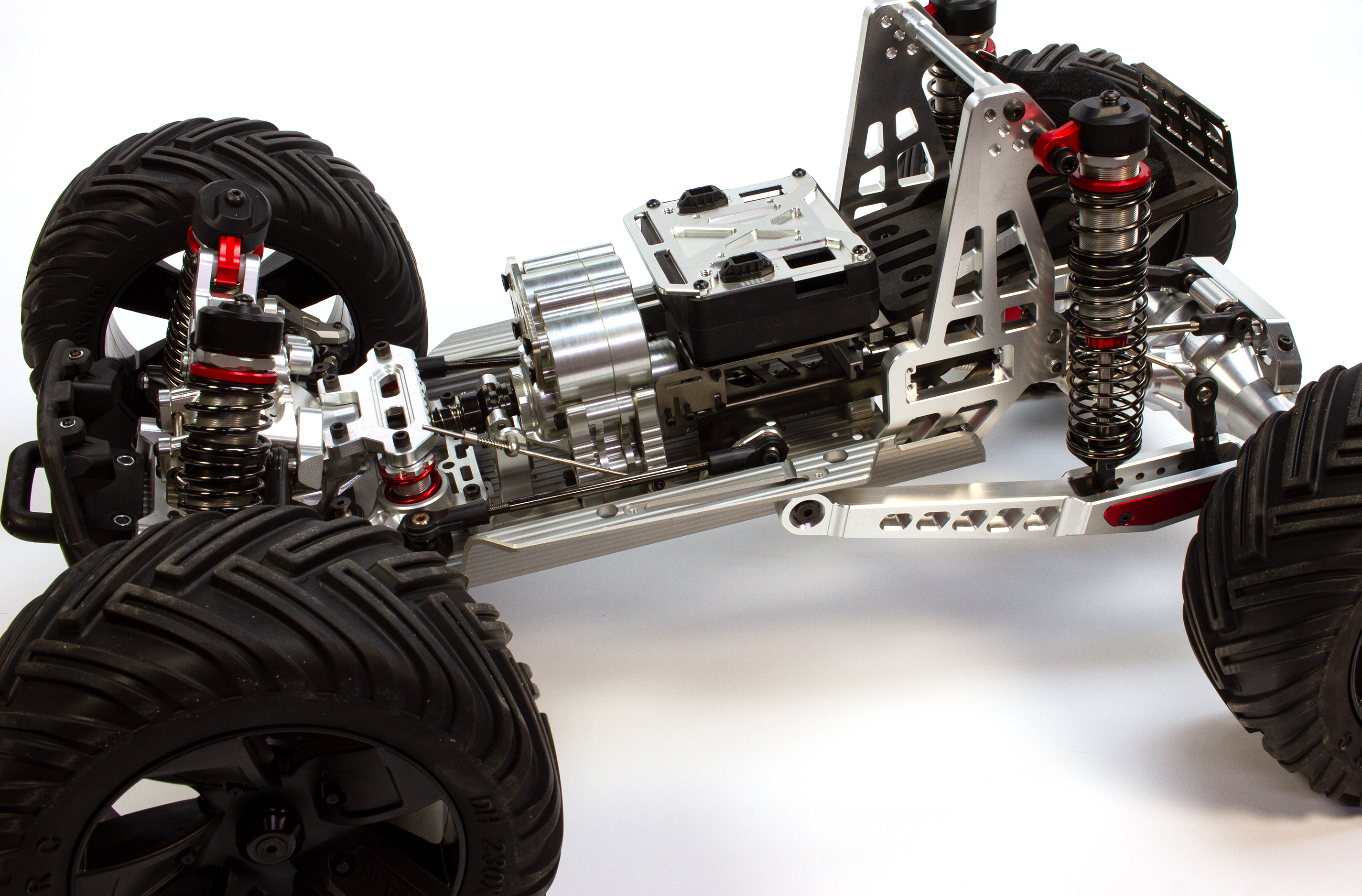

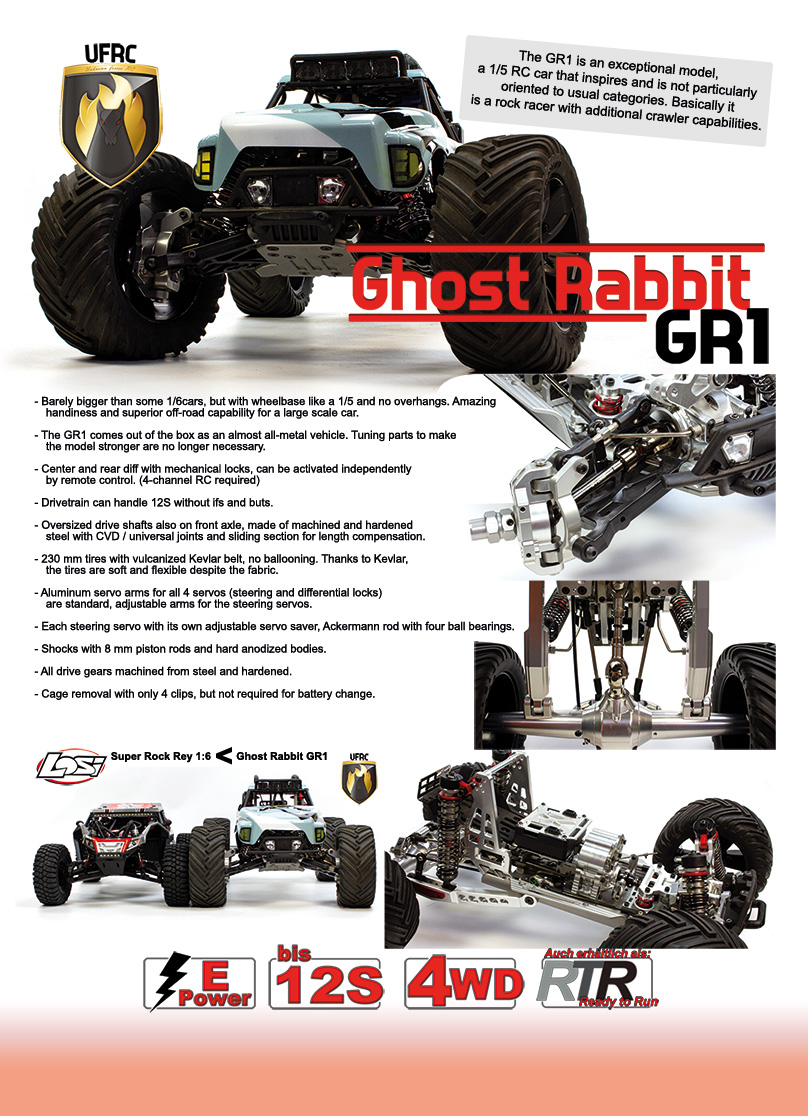

Ghost Rabbit GR1 - the new 4WD metal model from UFRC incl. RTR equipment!

- 2 pieces of 4S batteries with EC8 connectors (total max. size for both batteries combined: length 193 mm × width 125 mm × height 100 mm)

- Charger for LiPo batteries

- Its external dimensions are not much bigger than those of a 1/6 car, yet its wheelbase is on par with many 1/5 cars and it has no overhangs at all; its tires fit a monster truck (230 mm diameter!). This results in amazing handiness for a large scale car combined with outstanding off-road capability.

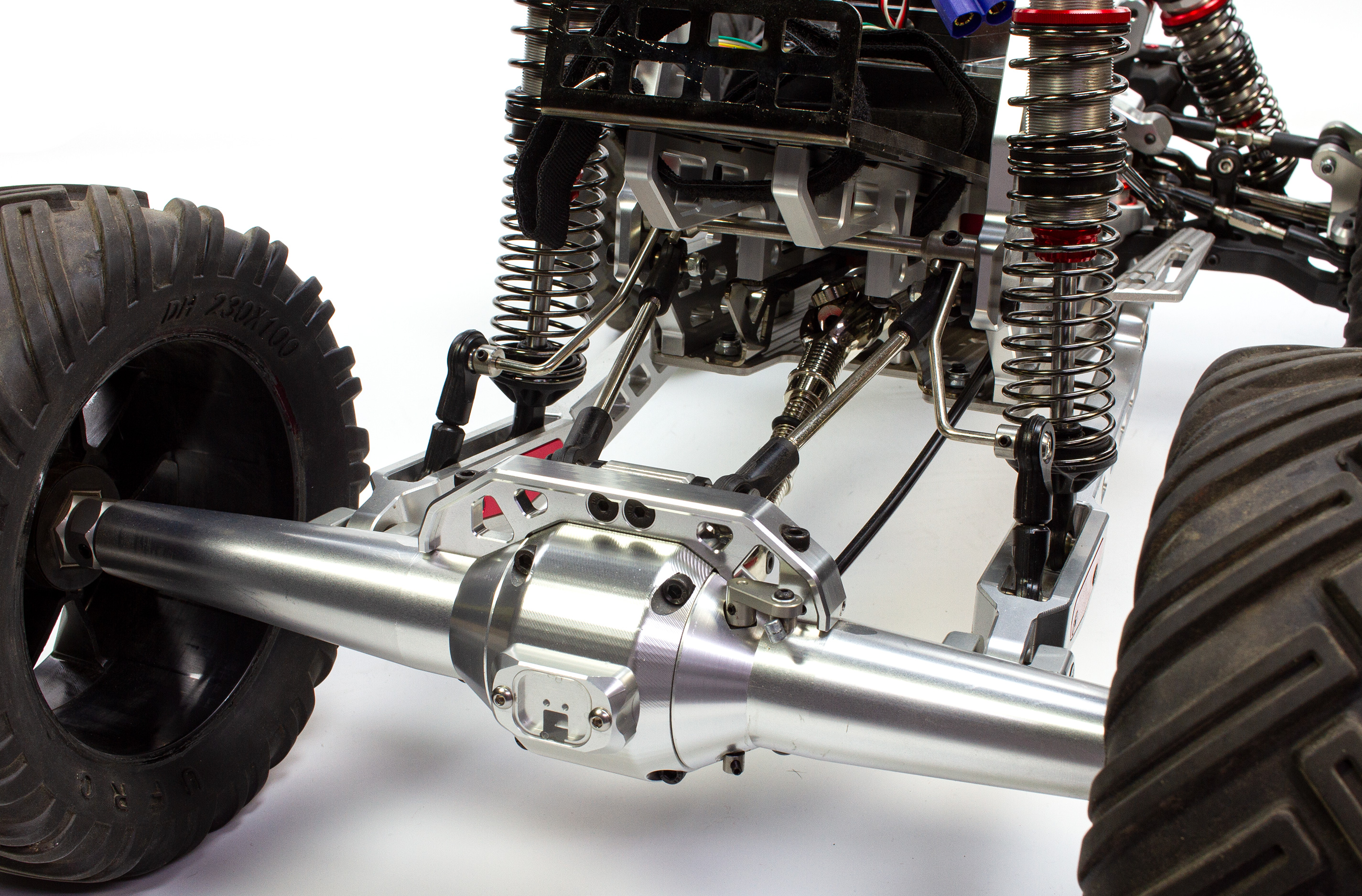

- The GR1 comes out of the box almost as an all-metal vehicle. Tuning parts to reinforce the model are no longer necessary.

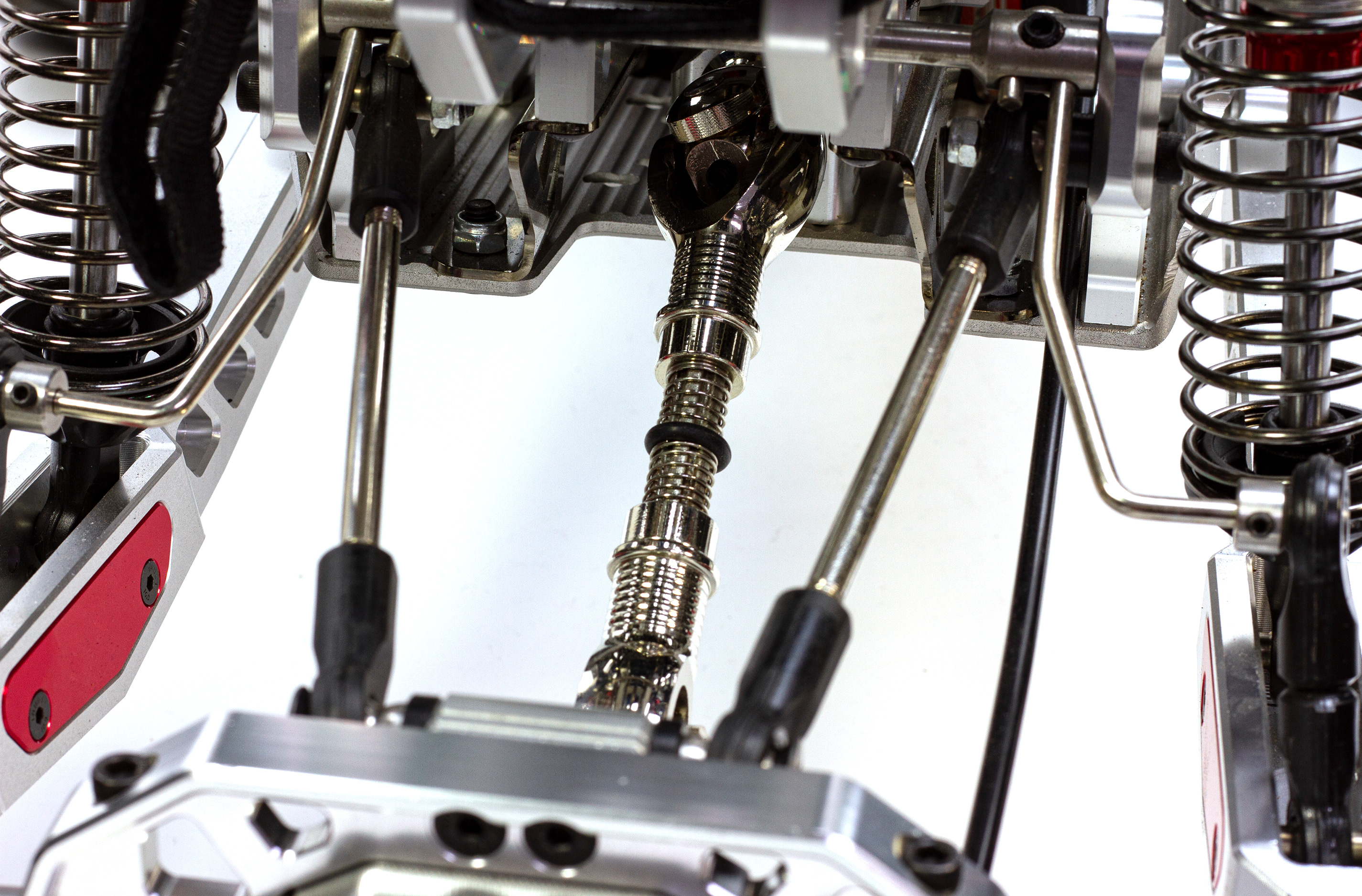

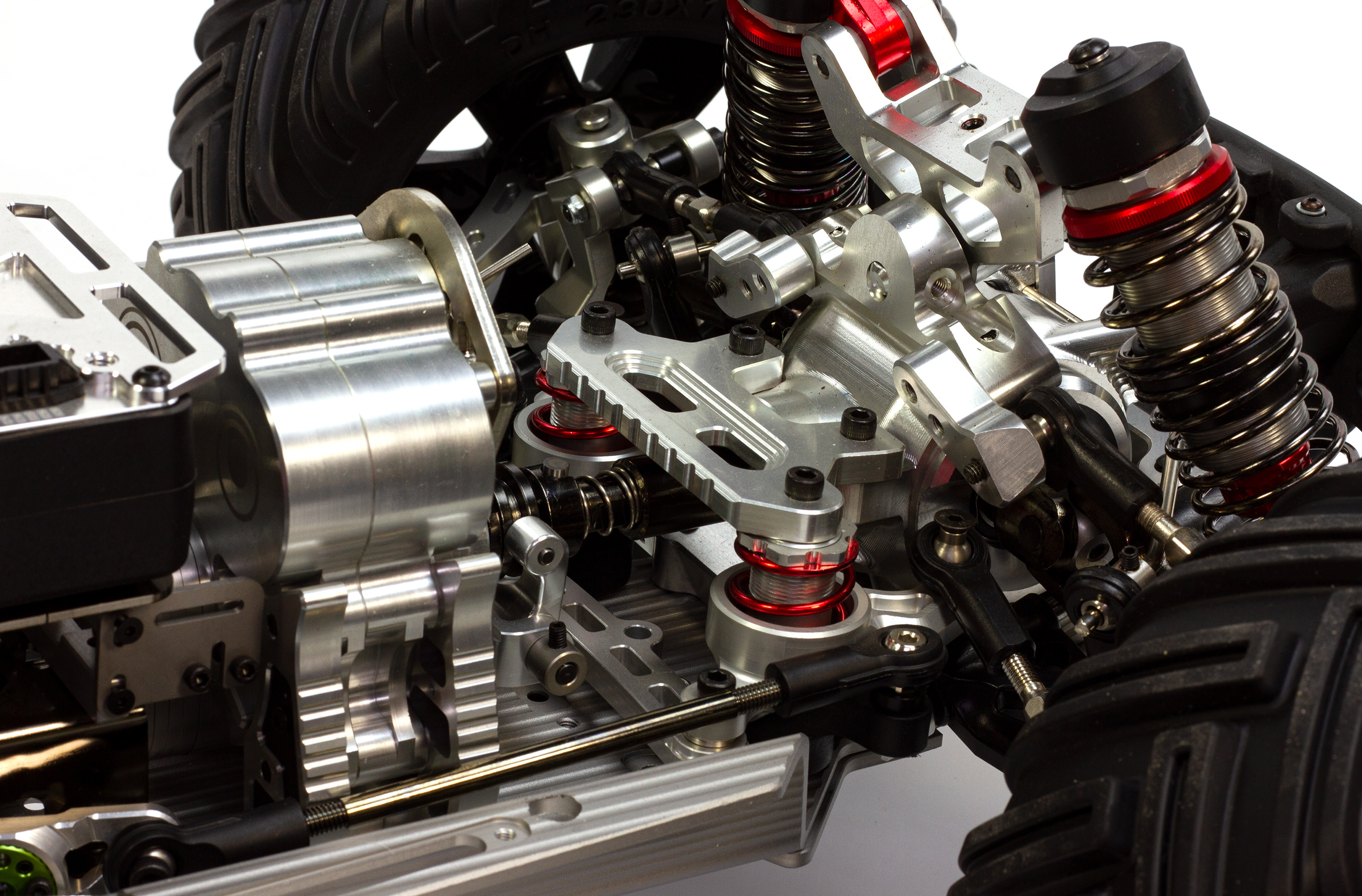

- Center and rear differential come standard with mechanical locks which can be activated independently by the radio. Of course, a radio system with the appropriate number of channels is required to use this feature.

- The dimensioning of all parts is designed for great reliability, e.g. the ball joints in the lower trailing arms are standardized industrial swivel bearings with an inner diameter of 6 mm, and the driveline can handle 12S hands down. But according to our experience, 12S operation is simply unnecessary.

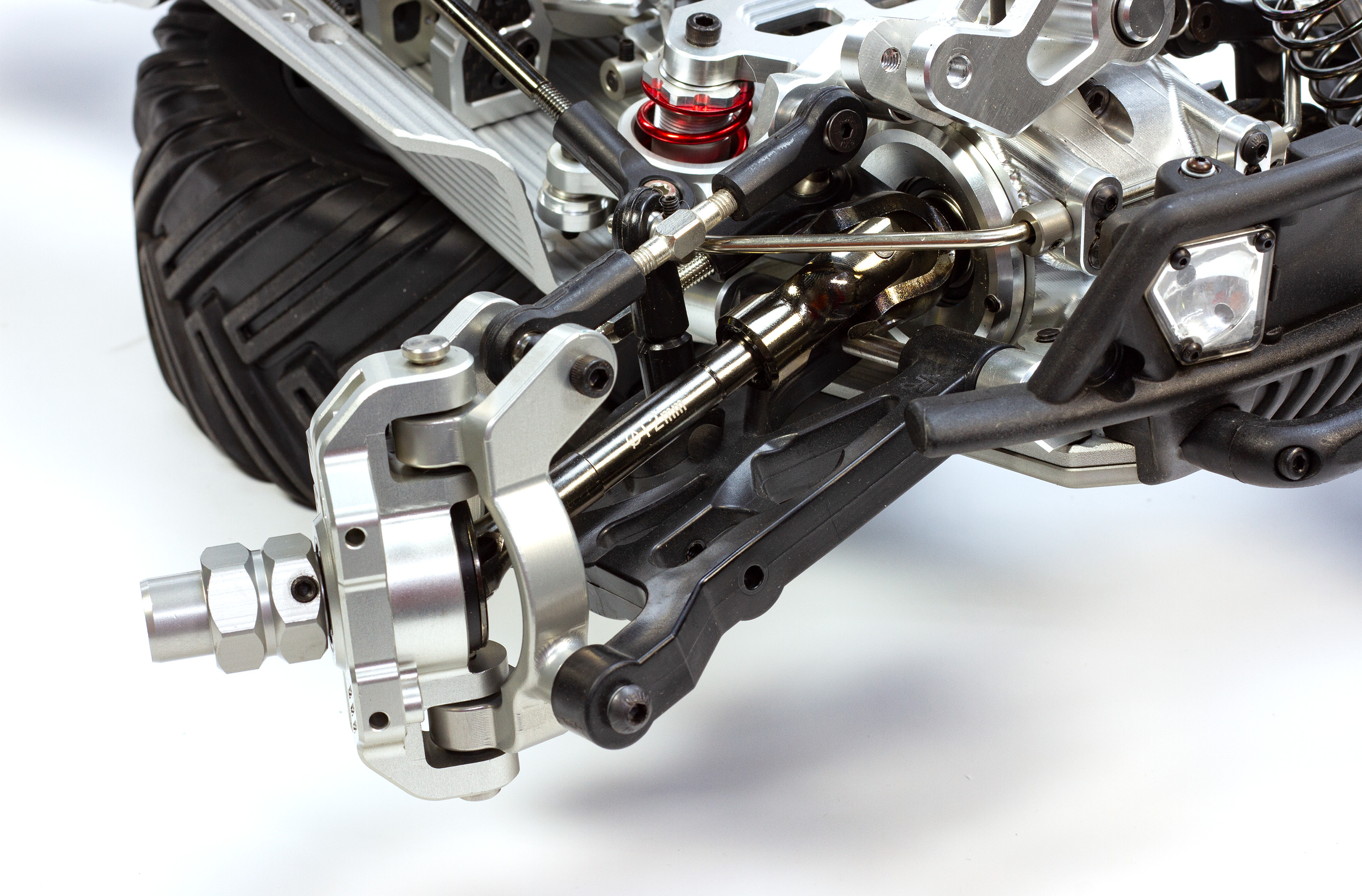

- Oversized drive shafts also on the front axle are machined and hardened steel with fixed joints at both ends and sliding piece for length compensation.

- The tires feature a vulcanized fabric reinforcement made of Kevlar; ballooning is actually a thing of the past for them. Thanks to Kevlar, the fabric belt can be relatively thin, so the tires are soft and flexible despite the fabric.

- Aluminum servo arms for all 4 servos (steering and differential locks) are standard. The levers of the two steering servos are adjustable.

- Each steering servo has its own adjustable servo saver. A stainless steel adjustment tool is included.

- The Ackerman rod features four ball bearings.

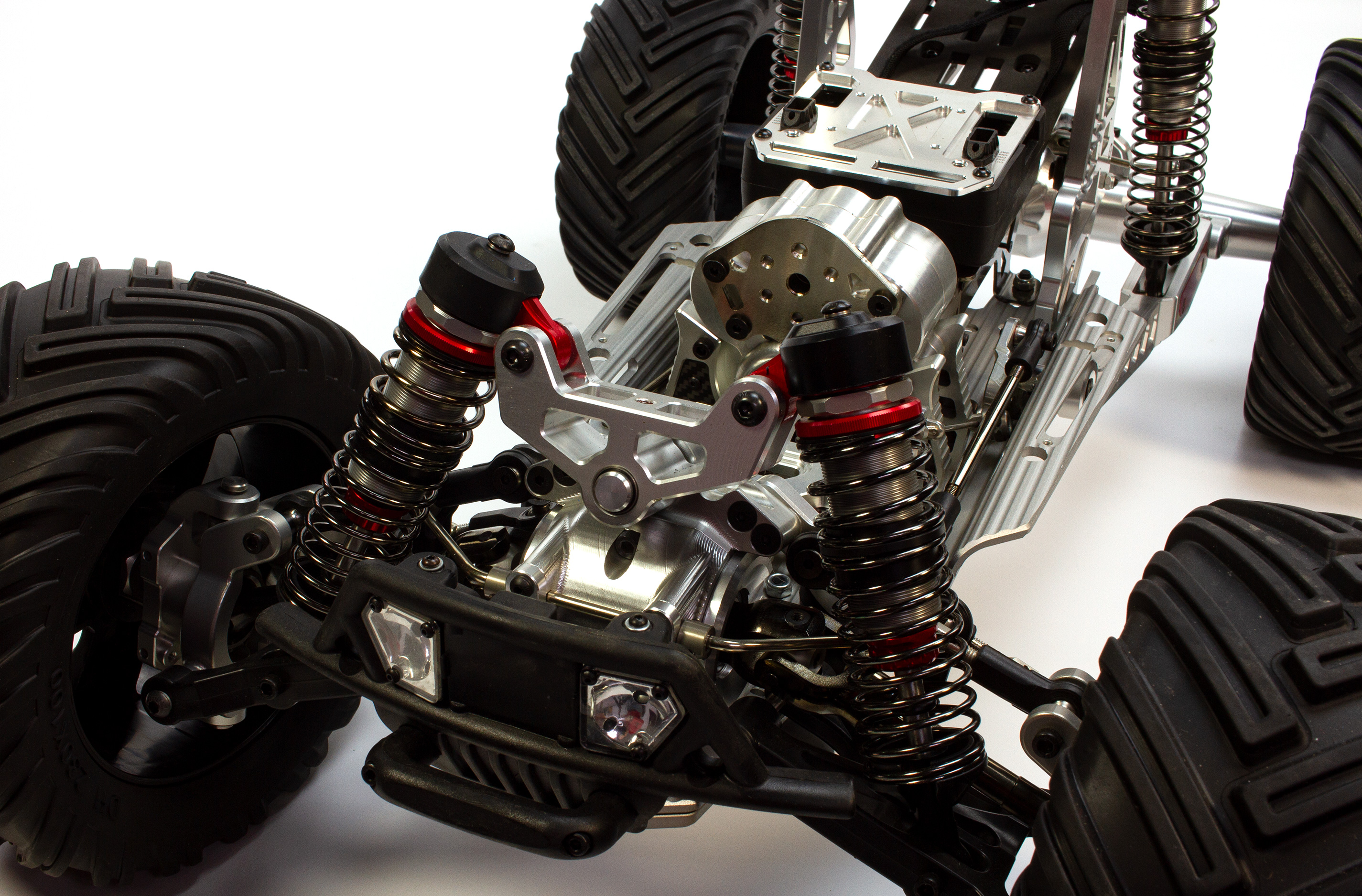

- Shock absorbers with 8 mm piston rods and hard anodized shock bodies.

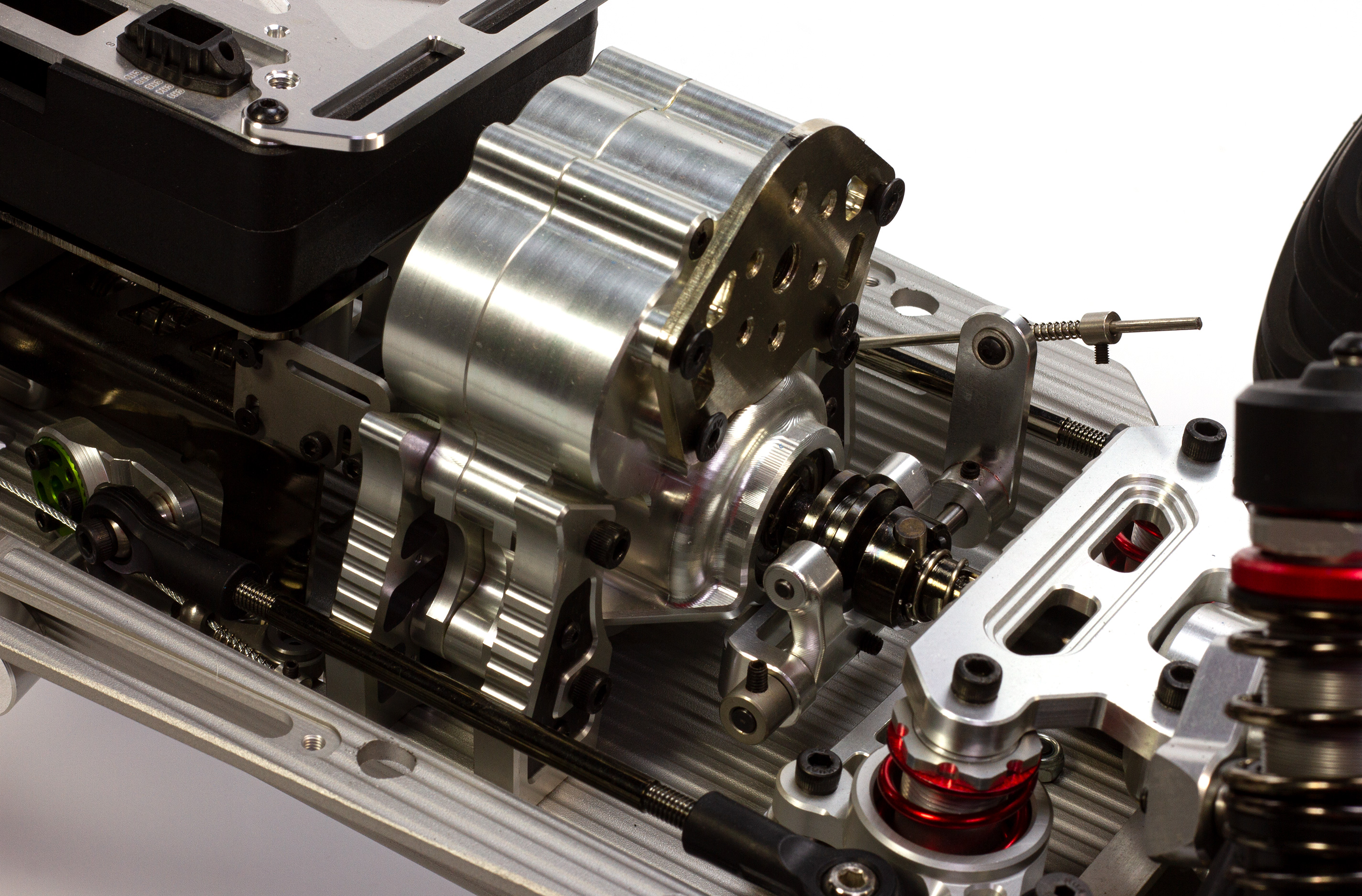

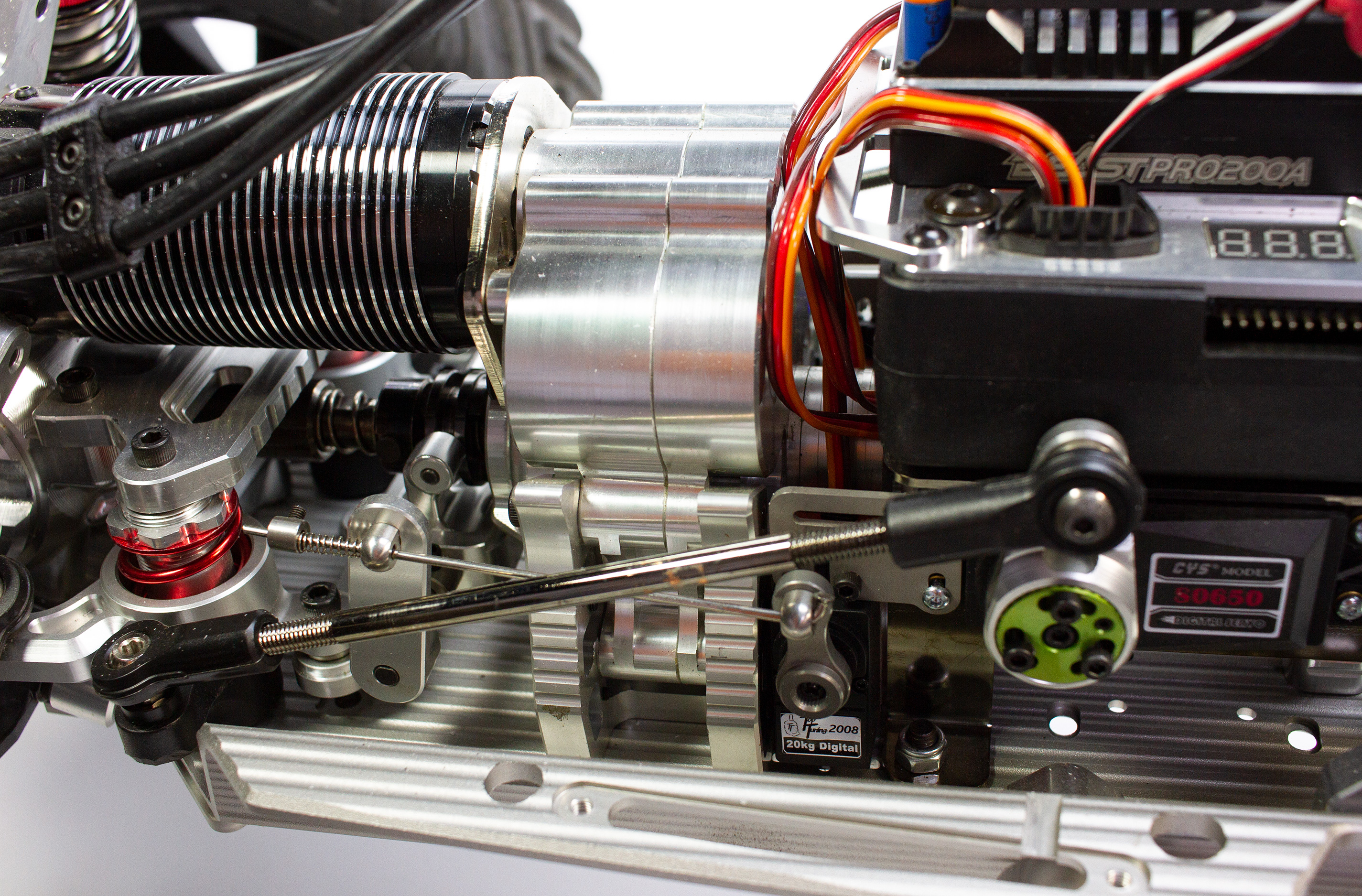

- All drive gears milled from steel and hardened.

- Two voltmeters can be optionally installed in the receiver box to monitor the traction batteries.

- The cage can be removed with only 4 clips, but even that is not a requirement for battery replacement.

Ghost Rabbit GR1 (1/5 4WD solid rear axle)

Main features of the 4WD Ghost Rabbit GR1:

- The strength of the components supports 12S power

- The wheelbase of 1/5 scale cars: 565mm

- The length of 1/6 scale cars: total length 790mm (when equipped with wheels with a diameter of 230mm)

- The whole car uses mostly metal parts, so there is no need to spend a lot of money on option parts later.

The weight of the GR1 ready to run with 2x batteries and 700KV motor is about 22 kg.

But if you think now that this is a ponderous steamroller, you better think again. A "Tank on speed" is a better description. Despite the weight, wheelies can be called up at any time thanks to the appropriate gear reduction, even if the controller is only set to level two of four in acceleration (punch).

At the same time, the possible twisting of the chassis is almost like that of a crawler. With the diff locks activated, the GR1 is almost unstoppable.

Technical details:

- Drive train: full-time 4WD with 3 differentials (remote rear and center differential lock as standard equipment)

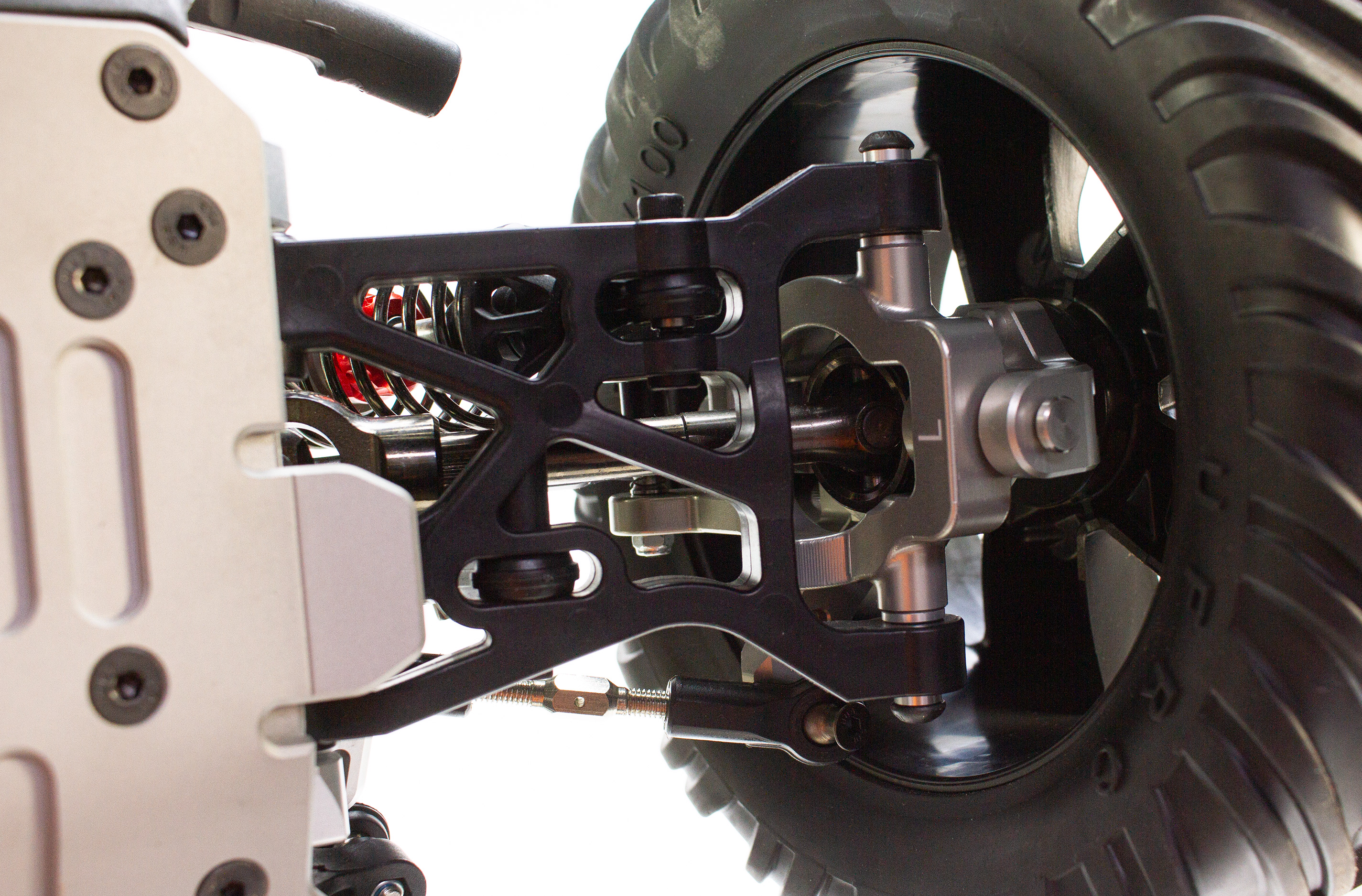

- Front suspension type: double a-arm IFS

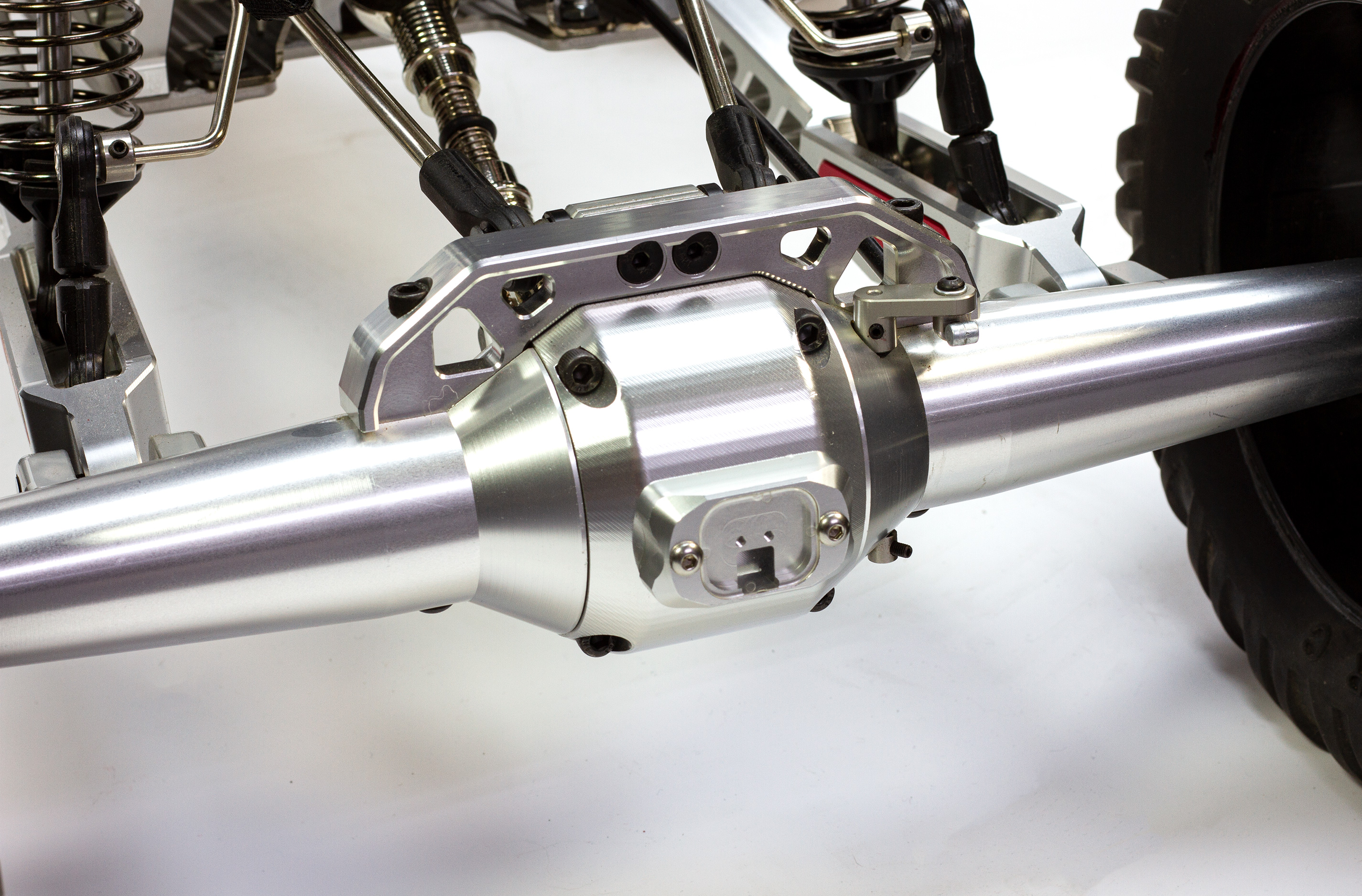

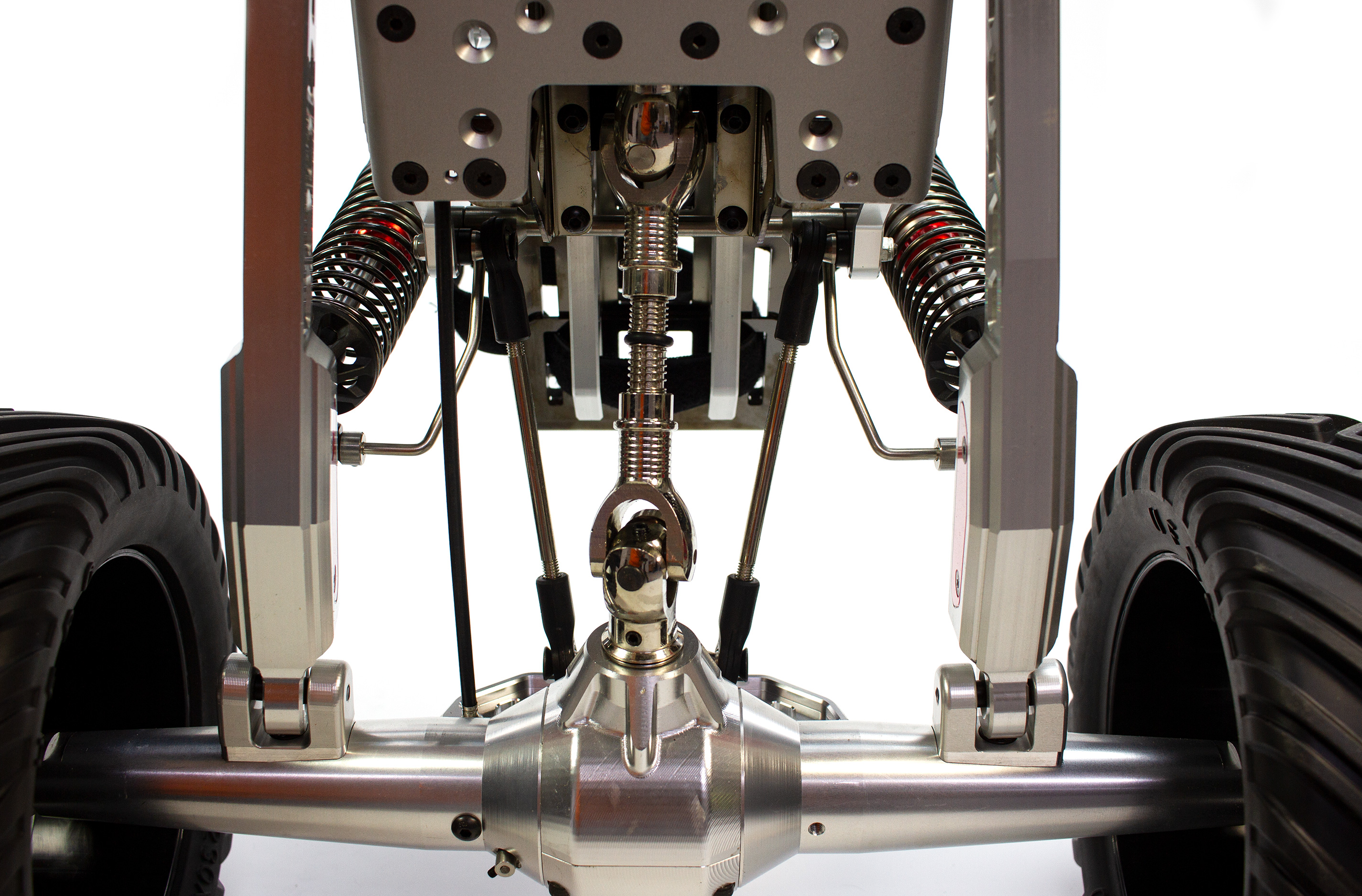

- Rear suspension type: solid rear axle with 4-link suspension

- Scale: 1/5

- Wheelbase: 565mm

- Front track width: 420mm

- Rear track width: 420mm

- Caster angle of kingpin: 20 degrees

- Front camber (adjustable): 3 degrees

- Toe-in (adjustable): 3 degrees

- Rear toe-in (not adjustable): 0 degrees

- Rear camber (not adjustable): 0 degrees

- Approach angle: about 90 degrees

- Departure angle: about 90 degrees

- Break-over angle: about 45 degrees

- Minimum turning radius: about 1.5 meters

- The maximum steering angle: about 30 degrees

- Maximum gradient: about 50 degrees

- Slide slope: about 40 degrees

- Maximum articulation: about 80 degrees (need to remove the front and rear anti-roll bars and loosen the angle limit screws of the front shock mounting beam)

- Lower trailing arm length (center/center of spherical bearings): 257 mm

- Chassis ground clearance (wheel diameter 230 mm): 115 mm

- Ground clearance under rear differential (wheel diameter 230 mm): 75 mm

- The maximum external dimensions of the vehicle body (length × width × height): 790 mm × 525 mm × 380 mm (with wheels of 230 mm diameter and 100 mm width)

- Gear ratio range: 9:1 to14.9:1 (The gear ratio can be changed by different gear set in the center gear box)

- Factory standard gear ratio: 14.9:1

- Gear modulus: M1.5

- Number of locking differentials: 2, servos for activation not included

- Locking differential positions: center and rear

- Wheel size: diameter 230 mm; width 100 mm. The tires feature Kevlar fiber belt to prevent ballooning and can handle 12S power

- Wheel drive size: 24 mm hex

- Front shocks mounting length (two-stage springs): 170 mm

- Front shock travel: 53 mm

- Rear shock mounting length (two-stage springs): 212mm

- Rear shock travel: 80 mm

- Calculated top speed:

- 8S power: 80 km/h (based on a 750KV motor)

- 12S power 110 km/h (based on a 680KV motor) (The maximum speed is calculated based on the electronic components and the actual numbers may vary)

- Weight of empty frame (excluding wheels and electronic components): 13.5 kg

- Total weight: approx. 22 kg

- Maximum payload of the frame: about 10 kg (do not press heavy objects or let people sit on the frame for driving operations, which may cause damage to parts)

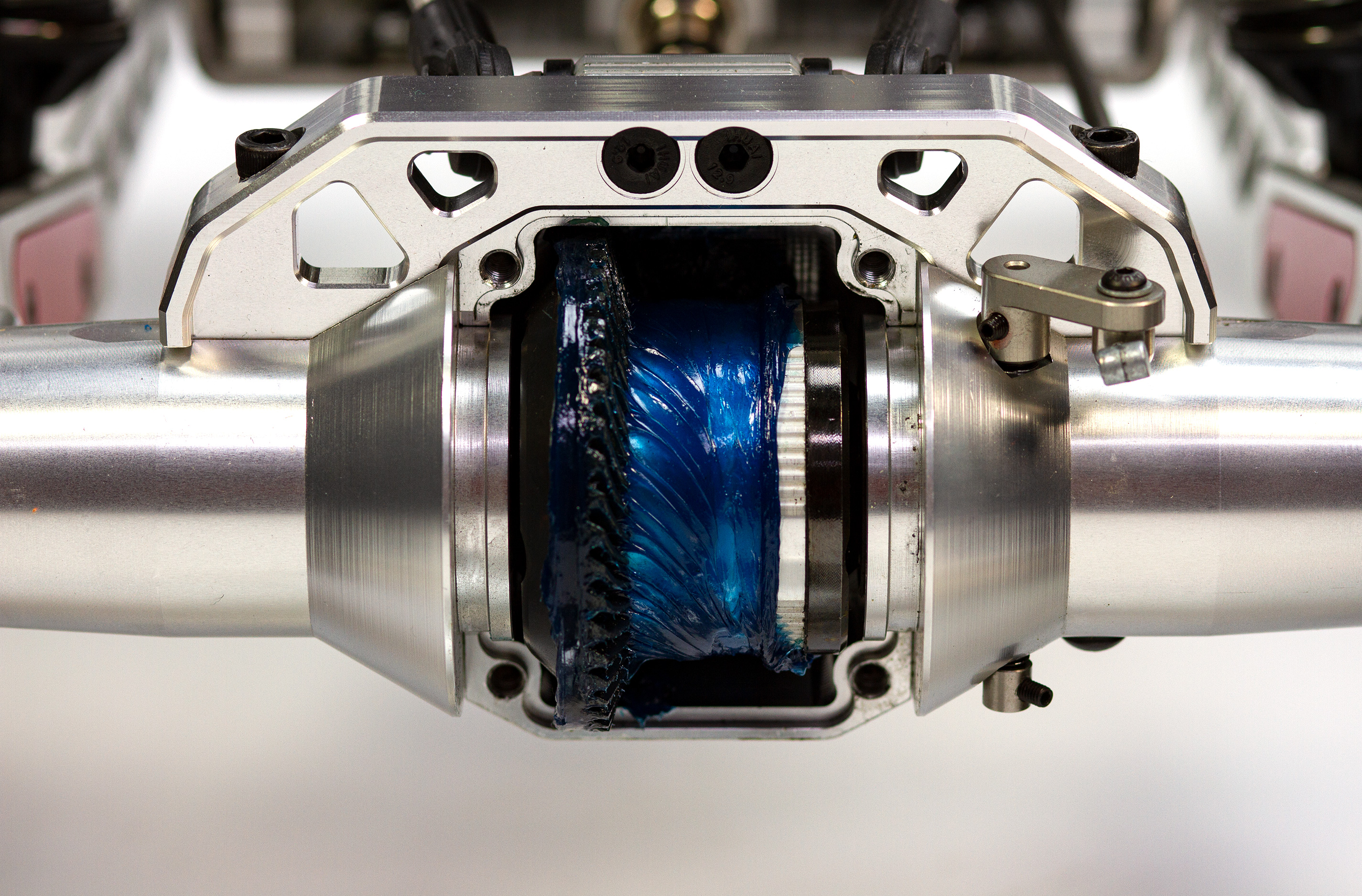

Lubricants parameters

- Front shock oil (silicone oil): 100cst

- Rear shock oil (silicone oil): 100cst

- Front differential oil (silicone oil): 300,000 cst

- Center differential oil (silicone oil): 300,000 cst

- Rear differential oil (silicone oil): 300,000 cst

- Front gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue)

- Center gear box (grease): Swedish molybdenum disulfide high temperature grease (blue)

- Rear axle gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue)

Frame materials and parts specifications, etc.

Chassis- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining, no stamp-out processing

- Surface treatment: hard anodizing and hardening

- Specifications: thickness 5 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining non-casting

- Surface treatment: hard anodizing and hardening

- Specifications: thickness 5 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: anodizing

- Specifications: The thickness of the part is 30 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: anodizing

- Specification: wall thickness 4 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: anodizing

- Specifications: wall thickness 2.5 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: anodizing

- Specifications: wall thickness 4 mm

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: hard anodizing and hardening

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC machining

- Surface treatment: hard anodizing and hardening

- Material: high-strength billet gear steel, non-powder metallurgy

- Processing technology: CNC gear hobbing machine

- Heat treatment process: carburizing and hardening

- Modulus: M1.5

- Material: high-strength billet gear steel, non-powder metallurgy

- Processing technology: CNC gear hobbing machine

- Heat treatment process: carburizing and hardening

- Modulus: M1.5

- Material: steel-based powder metallurgy

- Processing technology: hot isostatic pressing sintering

- Heat treatment process: vacuum

- Material: high-strength billet carbon steel

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Material: high-strength billet carbon steel

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Specifications: CVD end shaft diameter 12 mm; gearbox end universal joint maximum outer diameter 32mm

- Material: high-strength billet carbon steel

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Specification: shaft diameter 12 mm

- Material: high-strength billet carbon steel

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Specifications: The outer diameter of the spline telescopic shaft is 12 mm; the maximum diameter of the universal joint is 32 mm.

- Material: high-strength billet carbon steel

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Specifications: shaft diameter 12 mm, non-pin positive locking structure, shaft reaches into the differential planetary gear.

- Material: high strength nylon

- Material: high strength nylon

- Specification: diameter 10mm

- Material: Polycarbonate

- Specifications: thickness 1.5 mm

- Clear

Front and rear shock absorption main parts

Upper shock cap- Material: AL6061-T6 (aluminum)

- Processing technology: CNC

- Surface treatment: anodizing

- Material: AL6061-T6 (aluminum)

- Processing technology: CNC

- Surface treatment: hard anodizing and hardening

- Specification: barrel diameter 28mm

- Material: piano wire

- Surface treatment: black nickel plating

- Specification: front 2.8mm/rear 2.5mm

- Material: high-strength carbon steel

- Processing technology: high precision grinding

- Heat treatment: carburizing and hardening

- Specification: diameter 8mm

- Material: nylon

- Material: nylon

- Processing technology: CNC machined, no injection molding

- Material: silicone

- Front shock mounting beam: AL6061-T6 (aluminum)

- Rear shock tower: AL6061-T6 (aluminum)

- Servo fixing frame: AL6061-T6 (aluminum)

- Material: high-strength carbon steel

- Specification: 6mm

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Material: high-strength carbon steel

- Specification: 6mm

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Material: high-strength carbon steel

- Specification: 6 mm

- Processing technology: CNC

- Heat treatment process: carburizing and hardening

- Surface treatment: electroplating

- Material: SUS304 stainless steel

- Specification: ball diameter 11 mm

- Front lower A-arm: high-strength nylon

- Center gear box mounts: AL6061-T6 (aluminum)

- Lower trailing arm brackets: AL6061-T6 (aluminum)

- Adjustable steering servo arm (comes as standard!): AL6061-T6 (aluminum) (adjustment angle 20 degrees)

- Wheels

- Diameter: 230 mm

- Width: 100 mm

- Hexagonal drive: 24 mm

- Rim: high-strength nylon

- Tire skin: natural rubber (Kevlar fiber belted)

- Liner: high elastic sponge

- Hex drive: The hex insert is powder steel metallurgy, and the outer reinforcement ring is SUS304 stainless steel

General components:

- Wheels: Most 1/5 scale wheels with 24 mm hex drive and a diameter ranging from 190-230 mm and a width of 70-100 mm can be used. When the diameter is greater than 190 mm and the width is greater than 80 mm, the steering angle needs to be limited, and the steering angle has to be adjusted on the transmitter to about 75%. It is recommended to use wheels with a diameter of 230 mm and a width of 100 mm to maximize the performance and handling of the car.

- Differential spider gear assembly: HPI BAJA 5B compatible

- Nylon ball joints: 5ive-T size (ball diameter 11 mm)

- Electronic components configuration

- ESC

- Specification: 8S-12S

- Quantity: 1

- Specifications: market standard motor for 1/5 vehicles, such as 5692/56112/58113

- When using 8S power, the motor KV value should be lower than 800.

- When using 12S power, the motor KV value should be lower than 600. When selecting a 12S motor, you should accurately consult whether it supports 12S power. Improper selection may cause serious damage to the motor.

- The diameter of the motor shaft is 8 mm, and the depth of the flat surface is 1 mm.

- The protruding length of the motor shaft should be greater than 20 mm and less than 40 mm.

- Quantity: 1

- 8S: 2 groups of 4S (6,000-12,000 mAh) in series

- 12S: 2 sets of 6S (6,000-12,000 mAh) in series

- When choosing a battery, it should be noted that the three-dimensional size of the two batteries together cannot be larger than the size of the battery compartment.

- Quantity: 2 packs

- Battery compartment size: length 193 mm×width 125 mm×height 100mm

- Specification (15T output shaft): 50-85 kg

- Use common 1/5 model servos (mounting bolt pattern 17.5 mm×75 mm).

- Quantity: 2

- Specification (25T output shaft): 15-35 kg

- Use common 1/8 model steering servos ( mounting bolt pattern 10.0 mm × 49.5 mm), it is recommended to use 25 kg steering gear, but it should not be stronger than 35kg, which may easily cause the displacement of the differential lock limiter and change the pulling stroke. The differential lock function fails.

- Quantity: 2

- Type: car

- Channels: 5 channels or more (steering; throttle; differential lock uses two channels; car lighting (optional) channel)

- Quantity: one set

- Type: Equipped with lithium battery balancing function

- Specifications: 4S or above

- Quantity: one set

- Battery safe storage container

Common tools

Tool type: Allen key wrench; Hex wrenches; circlip pliersAllen wrench

- Sizes (metric system): 1.5 mm; 2.0 mm; 2.5 mm; 3.0 mm; 4.0 mm; 5.0 mm

- Sizes (metric system): 7 mm; 8 mm; 9 mm; 10 mm

- Type: external circlip pliers (when gripping the handle of the circlip pliers, the front end should open outward)

- Specifications: The diameter of the tip is less than 1mm, and the use range is 4-10mm

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Customers also viewed

Ghost Rabbit GR1 - the new 4WD metal model from UFRC Please note:In the basic configuration, the GR1 has a clear body and still requires remote control, servos, ESC, motor, 2 pieces driving batteries 6S mit EC8 Stecker (maximal dimensions: Length 193 mm x Width 125 mm x Height 100 mm) and charger for completion! Optionally available from the shopping cart selection of our online shop. Besides its excellent workmanship, there are many special details that clearly distinguish it from other vehicles on the market Its external dimensions are not much bigger than those of a 1/6 car, yet its wheelbase is on par with many 1/5 cars and it has no overhangs at all; its tires fit a monster truck (230 mm diameter!). This results in amazing handiness for a large scale car combined with outstanding off-road capability. The GR1 comes out of the box almost as an all-metal vehicle. Tuning parts to reinforce the model are no longer necessary. Center and rear differential come standard with mechanical locks which can be activated independently by the radio. Of course, a radio system with the appropriate number of channels is required to use this feature. The dimensioning of all parts is designed for great reliability, e.g. the ball joints in the lower trailing arms are standardized industrial swivel bearings with an inner diameter of 6 mm, and the driveline can handle 12S hands down. But according to our experience, 12S operation is simply unnecessary. Nevertheless, we offer 12S equipment in the options menu. Oversized drive shafts also on the front axle are machined and hardened steel with fixed joints at both ends and sliding piece for length compensation. The tires feature a vulcanized fabric reinforcement made of Kevlar; ballooning is actually a thing of the past for them. Thanks to Kevlar, the fabric belt can be relatively thin, so the tires are soft and flexible despite the fabric. Aluminum servo arms for all 4 servos (steering and differential locks) are standard. The levers of the two steering servos are adjustable. Each steering servo has its own adjustable servo saver. A stainless steel adjustment tool is included. The Ackerman rod features four ball bearings. Shock absorbers with 8 mm piston rods and hard anodized shock bodies. All drive gears milled from steel and hardened. Two voltmeters can be optionally installed in the receiver box to monitor the traction batteries. The cage can be removed with only 4 clips, but even that is not a requirement for battery replacement. Ghost Rabbit GR1 (1/5 4WD solid rear axle)Main features of the 4WD Ghost Rabbit GR1: The strength of the components supports 12S power The wheelbase of 1/5 scale cars: 565mm The length of 1/6 scale cars: total length 790mm (when equipped with wheels with a diameter of 230mm) The whole car uses mostly metal parts, so there is no need to spend a lot of money on option parts later. The weight of the GR1 ready to run with 2x 4S/10.000 mAh batteries and 700KV motor is about 22 kg.But if you think now that this is a ponderous steamroller, you better think again. A "Tank on speed" is a better description. Despite the weight, wheelies can be called up at any time thanks to the appropriate gear reduction, even if the controller is only set to level two of four in acceleration (punch).At the same time, the possible twisting of the chassis is almost like that of a crawler. With the diff locks activated, the GR1 is almost unstoppable.You need to supply these non-included items: motor; ESC; batteries; servos for steering and diff lock activation; radio system; charger; common tools, etc. Technical details: Drive train: full-time 4WD with 3 differentials (remote rear and center differential lock as standard equipment) Front suspension type: double a-arm IFS Rear suspension type: solid rear axle with 4-link suspension Scale: 1/5 Wheelbase: 565mm Front track width: 420mm Rear track width: 420mm Caster angle of kingpin: 20 degrees Front camber (adjustable): 3 degrees Toe-in (adjustable): 3 degrees Rear toe-in (not adjustable): 0 degrees Rear camber (not adjustable): 0 degrees Approach angle: about 90 degrees Departure angle: about 90 degrees Break-over angle: about 45 degrees Minimum turning radius: about 1.5 meters The maximum steering angle: about 30 degrees Maximum gradient: about 50 degrees Slide slope: about 40 degrees Maximum articulation: about 80 degrees (need to remove the front and rear anti-roll bars and loosen the angle limit screws of the front shock mounting beam) Lower trailing arm length (center/center of spherical bearings): 257 mm Chassis ground clearance (wheel diameter 230 mm): 115 mm Ground clearance under rear differential (wheel diameter 230 mm): 75 mm The maximum external dimensions of the vehicle body (length × width × height): 790 mm × 525 mm × 380 mm (with wheels of 230 mm diameter and 100 mm width) Gear ratio range: 9:1 to14.9:1 (The gear ratio can be changed by different gear set in the center gear box) Factory standard gear ratio: 14.9:1 Gear modulus: M1.5 Number of locking differentials: 2, servos for activation not included Locking differential positions: center and rear Wheel size: diameter 230 mm; width 100 mm. The tires feature Kevlar fiber belt to prevent ballooning and can handle 12S power Wheel drive size: 24 mm hex Front shocks mounting length (two-stage springs): 170 mm Front shock travel: 53 mm Rear shock mounting length (two-stage springs): 212mm Rear shock travel: 80 mm Calculated top speed: 8S power: 80 km/h (based on a 750KV motor) 12S power 110 km/h (based on a 680KV motor) (The maximum speed is calculated based on the electronic components and the actual numbers may vary) Weight of empty frame (excluding wheels and electronic components): 13.5 kg Total weight: approx. 22 kg Maximum payload of the frame: about 10 kg (do not press heavy objects or let people sit on the frame for driving operations, which may cause damage to parts) Lubricants parameters Front shock oil (silicone oil): 100cst Rear shock oil (silicone oil): 100cst Front differential oil (silicone oil): 300,000 cst Center differential oil (silicone oil): 300,000 cst Rear differential oil (silicone oil): 300,000 cst Front gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) Center gear box (grease): Swedish molybdenum disulfide high temperature grease (blue) Rear axle gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) (The above lubricants parameters are for reference only, and can be replaced according to your driving habits and environment) Frame materials and parts specifications, etc. Chassis Material: AL6061-T6 (aluminum) Processing technology: CNC machining, no stamp-out processing Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Front skid plate plate (standard configuration) Material: AL6061-T6 (aluminum) Processing technology: CNC machining non-casting Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Lower trailing arms Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: The thickness of the part is 30 mm Front gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specification: wall thickness 4 mm Center gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 2.5 mm Rear axle Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 4 mm Front spindles Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening C-Hubs Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening Differential ring and pinion (front and rear) Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Center gear box spur gears Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Differential spider gears Material: steel-based powder metallurgy Processing technology: hot isostatic pressing sintering Heat treatment process: vacuum Differential locking clutch Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Front suspension drive shaft (CVD structure at the wheel end, universal joint structure at the gear box end) Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: CVD end shaft diameter 12 mm; gearbox end universal joint maximum outer diameter 32mm Center drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specification: shaft diameter 12 mm Rear universal drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: The outer diameter of the spline telescopic shaft is 12 mm; the maximum diameter of the universal joint is 32 mm. Rear axle shafts Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: shaft diameter 12 mm, non-pin positive locking structure, shaft reaches into the differential planetary gear. Front bumper Material: high strength nylon Roll cage Material: high strength nylon Specification: diameter 10mm Car body shell panels Material: Polycarbonate Specifications: thickness 1.5 mm Receiver box: nylon Front and rear shock absorption main parts Upper shock cap Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: anodizing Shock body Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: hard anodizing and hardening Specification: barrel diameter 28mm Shock spring Material: piano wire Surface treatment: black nickel plating Specification: front 2.8mm/rear 2.5mm Shock piston rod Material: high-strength carbon steel Processing technology: high precision grinding Heat treatment: carburizing and hardening Specification: diameter 8mm Spring perches Material: nylon Piston Material: nylon Processing technology: CNC machined, no injection molding Sealing ring Material: silicone Front shock mounting beam: AL6061-T6 (aluminum) Rear shock tower: AL6061-T6 (aluminum) Servo fixing frame: AL6061-T6 (aluminum) Steering rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Steering linkage rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Rear axle stabilizer bar Material: high-strength carbon steel Specification: 6 mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Ball heads Material: SUS304 stainless steel Specification: ball diameter 11 mm Front lower A-arm: high-strength nylon Center gear box mounts: AL6061-T6 (aluminum) Lower trailing arm brackets: AL6061-T6 (aluminum) Adjustable steering servo arm (comes as standard!): AL6061-T6 (aluminum) (adjustment angle 20 degrees) Wheels Specifications Diameter: 230 mm Width: 100 mm Hexagonal drive: 24 mm Material Rim: high-strength nylon Tire skin: natural rubber (Kevlar fiber belted) Liner: high elastic sponge Hex drive: The hex insert is powder steel metallurgy, and the outer reinforcement ring is SUS304 stainless steel All vehicle screws: 10.9 grade carbon steel General components: Wheels: Most 1/5 scale wheels with 24 mm hex drive and a diameter ranging from 190-230 mm and a width of 70-100 mm can be used. When the diameter is greater than 190 mm and the width is greater than 80 mm, the steering angle needs to be limited, and the steering angle has to be adjusted on the transmitter to about 75%. It is recommended to use wheels with a diameter of 230 mm and a width of 100 mm to maximize the performance and handling of the car. Differential spider gear assembly: HPI BAJA 5B compatible Nylon ball joints: 5ive-T size (ball diameter 11 mm) Electronic components configuration ESC Specification: 8S-12S Quantity: 1 Motor Specifications: market standard motor for 1/5 vehicles, such as 5692/56112/58113 When using 8S power, the motor KV value should be lower than 800. When using 12S power, the motor KV value should be lower than 600. When selecting a 12S motor, you should accurately consult whether it supports 12S power. Improper selection may cause serious damage to the motor. The diameter of the motor shaft is 8 mm, and the depth of the flat surface is 1 mm. The protruding length of the motor shaft should be greater than 20 mm and less than 40 mm. Quantity: 1 Battery 8S: 2 groups of 4S (6,000-12,000 mAh) in series 12S: 2 sets of 6S (6,000-12,000 mAh) in series When choosing a battery, it should be noted that the three-dimensional size of the two batteries together cannot be larger than the size of the battery compartment. Quantity: 2 packs Battery compartment size: length 193 mm×width 125 mm×height 100mm Steering servo: Specification (15T output shaft): 50-85 kg Use common 1/5 model servos (mounting bolt pattern 17.5 mm×75 mm). Quantity: 2 Differential lock servo Specification (25T output shaft): 15-35 kg Use common 1/8 model steering servos ( mounting bolt pattern 10.0 mm × 49.5 mm), it is recommended to use 25 kg steering gear, but it should not be stronger than 35kg, which may easily cause the displacement of the differential lock limiter and change the pulling stroke. The differential lock function fails. Quantity: 2 Remote control Type: car Channels: 5 channels or more (steering; throttle; differential lock uses two channels; car lighting (optional) channel) Quantity: one set Charger Type: Equipped with lithium battery balancing function Specifications: 4S or above Quantity: one set Battery safe storage container Common tools Tool type: Allen key wrench; Hex wrenches; circlip pliers Allen wrench Sizes (metric system): 1.5 mm; 2.0 mm; 2.5 mm; 3.0 mm; 4.0 mm; 5.0 mm Hex wrenches Sizes (metric system): 7 mm; 8 mm; 9 mm; 10 mm Circlip pliers Type: external circlip pliers (when gripping the handle of the circlip pliers, the front end should open outward) Specifications: The diameter of the tip is less than 1mm, and the use range is 4-10mm

Ghost Rabbit GR1 - the new 4WD metal model from UFRC incl. RTR equipment! TT56112 Top Tuning Monster Brushless Motor 700 kV ESC Spektrum 160A Regler 2x Voltmeter Spektrum DX5C Smart 5CH DSMR radio control incl. SPMSR515 receiver 2 pieces y1570 CYS S0650 large scale servo, 55 kg/0,11 sec for Steering 2 pieces y2009 Top Tuning Digital pro Servo 25 kg for Differential lock Required for completion: 2 pieces of 4S batteries with EC8 connectors (total max. size for both batteries combined: length 193 mm × width 125 mm × height 100 mm) Charger for LiPo batteries Its external dimensions are not much bigger than those of a 1/6 car, yet its wheelbase is on par with many 1/5 cars and it has no overhangs at all; its tires fit a monster truck (230 mm diameter!). This results in amazing handiness for a large scale car combined with outstanding off-road capability. The GR1 comes out of the box almost as an all-metal vehicle. Tuning parts to reinforce the model are no longer necessary. Center and rear differential come standard with mechanical locks which can be activated independently by the radio. Of course, a radio system with the appropriate number of channels is required to use this feature. The dimensioning of all parts is designed for great reliability, e.g. the ball joints in the lower trailing arms are standardized industrial swivel bearings with an inner diameter of 6 mm, and the driveline can handle 12S hands down. But according to our experience, 12S operation is simply unnecessary. Oversized drive shafts also on the front axle are machined and hardened steel with fixed joints at both ends and sliding piece for length compensation. The tires feature a vulcanized fabric reinforcement made of Kevlar; ballooning is actually a thing of the past for them. Thanks to Kevlar, the fabric belt can be relatively thin, so the tires are soft and flexible despite the fabric. Aluminum servo arms for all 4 servos (steering and differential locks) are standard. The levers of the two steering servos are adjustable. Each steering servo has its own adjustable servo saver. A stainless steel adjustment tool is included. The Ackerman rod features four ball bearings. Shock absorbers with 8 mm piston rods and hard anodized shock bodies. All drive gears milled from steel and hardened. Two voltmeters can be optionally installed in the receiver box to monitor the traction batteries. The cage can be removed with only 4 clips, but even that is not a requirement for battery replacement. Ghost Rabbit GR1 (1/5 4WD solid rear axle)Main features of the 4WD Ghost Rabbit GR1: The strength of the components supports 12S power The wheelbase of 1/5 scale cars: 565mm The length of 1/6 scale cars: total length 790mm (when equipped with wheels with a diameter of 230mm) The whole car uses mostly metal parts, so there is no need to spend a lot of money on option parts later. The weight of the GR1 ready to run with 2x batteries and 700KV motor is about 22 kg.But if you think now that this is a ponderous steamroller, you better think again. A "Tank on speed" is a better description. Despite the weight, wheelies can be called up at any time thanks to the appropriate gear reduction, even if the controller is only set to level two of four in acceleration (punch).At the same time, the possible twisting of the chassis is almost like that of a crawler. With the diff locks activated, the GR1 is almost unstoppable. Technical details: Drive train: full-time 4WD with 3 differentials (remote rear and center differential lock as standard equipment) Front suspension type: double a-arm IFS Rear suspension type: solid rear axle with 4-link suspension Scale: 1/5 Wheelbase: 565mm Front track width: 420mm Rear track width: 420mm Caster angle of kingpin: 20 degrees Front camber (adjustable): 3 degrees Toe-in (adjustable): 3 degrees Rear toe-in (not adjustable): 0 degrees Rear camber (not adjustable): 0 degrees Approach angle: about 90 degrees Departure angle: about 90 degrees Break-over angle: about 45 degrees Minimum turning radius: about 1.5 meters The maximum steering angle: about 30 degrees Maximum gradient: about 50 degrees Slide slope: about 40 degrees Maximum articulation: about 80 degrees (need to remove the front and rear anti-roll bars and loosen the angle limit screws of the front shock mounting beam) Lower trailing arm length (center/center of spherical bearings): 257 mm Chassis ground clearance (wheel diameter 230 mm): 115 mm Ground clearance under rear differential (wheel diameter 230 mm): 75 mm The maximum external dimensions of the vehicle body (length × width × height): 790 mm × 525 mm × 380 mm (with wheels of 230 mm diameter and 100 mm width) Gear ratio range: 9:1 to14.9:1 (The gear ratio can be changed by different gear set in the center gear box) Factory standard gear ratio: 14.9:1 Gear modulus: M1.5 Number of locking differentials: 2, servos for activation not included Locking differential positions: center and rear Wheel size: diameter 230 mm; width 100 mm. The tires feature Kevlar fiber belt to prevent ballooning and can handle 12S power Wheel drive size: 24 mm hex Front shocks mounting length (two-stage springs): 170 mm Front shock travel: 53 mm Rear shock mounting length (two-stage springs): 212mm Rear shock travel: 80 mm Calculated top speed: 8S power: 80 km/h (based on a 750KV motor) 12S power 110 km/h (based on a 680KV motor) (The maximum speed is calculated based on the electronic components and the actual numbers may vary) Weight of empty frame (excluding wheels and electronic components): 13.5 kg Total weight: approx. 22 kg Maximum payload of the frame: about 10 kg (do not press heavy objects or let people sit on the frame for driving operations, which may cause damage to parts) Lubricants parameters Front shock oil (silicone oil): 100cst Rear shock oil (silicone oil): 100cst Front differential oil (silicone oil): 300,000 cst Center differential oil (silicone oil): 300,000 cst Rear differential oil (silicone oil): 300,000 cst Front gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) Center gear box (grease): Swedish molybdenum disulfide high temperature grease (blue) Rear axle gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) (The above lubricants parameters are for reference only, and can be replaced according to your driving habits and environment) Frame materials and parts specifications, etc. Chassis Material: AL6061-T6 (aluminum) Processing technology: CNC machining, no stamp-out processing Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Front skid plate plate (standard configuration) Material: AL6061-T6 (aluminum) Processing technology: CNC machining non-casting Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Lower trailing arms Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: The thickness of the part is 30 mm Front gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specification: wall thickness 4 mm Center gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 2.5 mm Rear axle Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 4 mm Front spindles Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening C-Hubs Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening Differential ring and pinion (front and rear) Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Center gear box spur gears Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Differential spider gears Material: steel-based powder metallurgy Processing technology: hot isostatic pressing sintering Heat treatment process: vacuum Differential locking clutch Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Front suspension drive shaft (CVD structure at the wheel end, universal joint structure at the gear box end) Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: CVD end shaft diameter 12 mm; gearbox end universal joint maximum outer diameter 32mm Center drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specification: shaft diameter 12 mm Rear universal drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: The outer diameter of the spline telescopic shaft is 12 mm; the maximum diameter of the universal joint is 32 mm. Rear axle shafts Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: shaft diameter 12 mm, non-pin positive locking structure, shaft reaches into the differential planetary gear. Front bumper Material: high strength nylon Roll cage Material: high strength nylon Specification: diameter 10mm Car body shell panels Material: Polycarbonate Specifications: thickness 1.5 mm Clear Receiver box: nylon Front and rear shock absorption main parts Upper shock cap Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: anodizing Shock body Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: hard anodizing and hardening Specification: barrel diameter 28mm Shock spring Material: piano wire Surface treatment: black nickel plating Specification: front 2.8mm/rear 2.5mm Shock piston rod Material: high-strength carbon steel Processing technology: high precision grinding Heat treatment: carburizing and hardening Specification: diameter 8mm Spring perches Material: nylon Piston Material: nylon Processing technology: CNC machined, no injection molding Sealing ring Material: silicone Front shock mounting beam: AL6061-T6 (aluminum) Rear shock tower: AL6061-T6 (aluminum) Servo fixing frame: AL6061-T6 (aluminum) Steering rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Steering linkage rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Rear axle stabilizer bar Material: high-strength carbon steel Specification: 6 mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Ball heads Material: SUS304 stainless steel Specification: ball diameter 11 mm Front lower A-arm: high-strength nylon Center gear box mounts: AL6061-T6 (aluminum) Lower trailing arm brackets: AL6061-T6 (aluminum) Adjustable steering servo arm (comes as standard!): AL6061-T6 (aluminum) (adjustment angle 20 degrees) Wheels Specifications Diameter: 230 mm Width: 100 mm Hexagonal drive: 24 mm Material Rim: high-strength nylon Tire skin: natural rubber (Kevlar fiber belted) Liner: high elastic sponge Hex drive: The hex insert is powder steel metallurgy, and the outer reinforcement ring is SUS304 stainless steel All vehicle screws: 10.9 grade carbon steel General components: Wheels: Most 1/5 scale wheels with 24 mm hex drive and a diameter ranging from 190-230 mm and a width of 70-100 mm can be used. When the diameter is greater than 190 mm and the width is greater than 80 mm, the steering angle needs to be limited, and the steering angle has to be adjusted on the transmitter to about 75%. It is recommended to use wheels with a diameter of 230 mm and a width of 100 mm to maximize the performance and handling of the car. Differential spider gear assembly: HPI BAJA 5B compatible Nylon ball joints: 5ive-T size (ball diameter 11 mm) Electronic components configuration ESC Specification: 8S-12S Quantity: 1 Motor Specifications: market standard motor for 1/5 vehicles, such as 5692/56112/58113 When using 8S power, the motor KV value should be lower than 800. When using 12S power, the motor KV value should be lower than 600. When selecting a 12S motor, you should accurately consult whether it supports 12S power. Improper selection may cause serious damage to the motor. The diameter of the motor shaft is 8 mm, and the depth of the flat surface is 1 mm. The protruding length of the motor shaft should be greater than 20 mm and less than 40 mm. Quantity: 1 Battery 8S: 2 groups of 4S (6,000-12,000 mAh) in series 12S: 2 sets of 6S (6,000-12,000 mAh) in series When choosing a battery, it should be noted that the three-dimensional size of the two batteries together cannot be larger than the size of the battery compartment. Quantity: 2 packs Battery compartment size: length 193 mm×width 125 mm×height 100mm Steering servo: Specification (15T output shaft): 50-85 kg Use common 1/5 model servos (mounting bolt pattern 17.5 mm×75 mm). Quantity: 2 Differential lock servo Specification (25T output shaft): 15-35 kg Use common 1/8 model steering servos ( mounting bolt pattern 10.0 mm × 49.5 mm), it is recommended to use 25 kg steering gear, but it should not be stronger than 35kg, which may easily cause the displacement of the differential lock limiter and change the pulling stroke. The differential lock function fails. Quantity: 2 Remote control Type: car Channels: 5 channels or more (steering; throttle; differential lock uses two channels; car lighting (optional) channel) Quantity: one set Charger Type: Equipped with lithium battery balancing function Specifications: 4S or above Quantity: one set Battery safe storage container Common tools Tool type: Allen key wrench; Hex wrenches; circlip pliers Allen wrench Sizes (metric system): 1.5 mm; 2.0 mm; 2.5 mm; 3.0 mm; 4.0 mm; 5.0 mm Hex wrenches Sizes (metric system): 7 mm; 8 mm; 9 mm; 10 mm Circlip pliers Type: external circlip pliers (when gripping the handle of the circlip pliers, the front end should open outward) Specifications: The diameter of the tip is less than 1mm, and the use range is 4-10mm

Big Bully GR1 - the new 4WD metal model from UFRC incl. RTR equipment! TT56112/520Top Tuning Monster Brushless Motor 520kV HW3010420 Hobbywing Ezrun MAX5 HV G2250 Amp ESC Spektrum DX6C 6-Channel DSMR Transmitter with SR315 Receiver 2 pieces y1570 CYS S0650 large scale servo, 55 kg/0,11 sec for Steering 2 pieces y2009 Top Tuning Digital pro Servo 25 kg for Differential lock Required for completion: 2 pieces of 6S batteries with EC8 connectors (total max. size for both batteries combined: length 193 mm × width 125 mm × height 100 mm) Charger for LiPo batteries Besides its excellent workmanship, there are many special details that clearly distinguish it from other vehicles on the market: Its external dimensions are not much bigger than those of a 1/6 car, yet its wheelbase is on par with many 1/5 cars and it has no overhangs at all; its tires fit a monster truck (230 mm diameter!). This results in amazing handiness for a large scale car combined with outstanding off-road capability. The GR1 comes out of the box almost as an all-metal vehicle. Tuning parts to reinforce the model are no longer necessary. Center and rear differential come standard with mechanical locks which can be activated independently by the radio. Of course, a radio system with the appropriate number of channels is required to use this feature. The dimensioning of all parts is designed for great reliability, e.g. the ball joints in the lower trailing arms are standardized industrial swivel bearings with an inner diameter of 6 mm, and the driveline can handle 12S hands down. But according to our experience, 12S operation is simply unnecessary. Nevertheless, we offer 12S equipment in the options menu. Oversized drive shafts also on the front axle are machined and hardened steel with fixed joints at both ends and sliding piece for length compensation. The tires feature a vulcanized fabric reinforcement made of Kevlar; ballooning is actually a thing of the past for them. Thanks to Kevlar, the fabric belt can be relatively thin, so the tires are soft and flexible despite the fabric. Aluminum servo arms for all 4 servos (steering and differential locks) are standard. The levers of the two steering servos are adjustable. Each steering servo has its own adjustable servo saver. A stainless steel adjustment tool is included. The Ackerman rod features four ball bearings. Shock absorbers with 8 mm piston rods and hard anodized shock bodies. All drive gears milled from steel and hardened. Two voltmeters can be optionally installed in the receiver box to monitor the traction batteries. The cage can be removed with only 4 clips, but even that is not a requirement for battery replacement. Inclusive original FG Monster Buggy body shell with rear wing. Big Bully GR1 (1/5 4WD solid rear axle)Main features of the 4WD Big Bully GR1: The strength of the components supports 12S power The wheelbase of 1/5 scale cars: 565mm The length of 1/6 scale cars: total length 790mm (when equipped with wheels with a diameter of 230mm) The whole car uses mostly metal parts, so there is no need to spend a lot of money on option parts later. The weight of the GR1 ready to run with 2x 4S/10.000 mAh batteries and 700KV motor is about 22 kg.But if you think now that this is a ponderous steamroller, you better think again. A "Tank on speed" is a better description. Despite the weight, wheelies can be called up at any time thanks to the appropriate gear reduction, even if the controller is only set to level two of four in acceleration (punch).At the same time, the possible twisting of the chassis is almost like that of a crawler. With the diff locks activated, the GR1 is almost unstoppable. Technical details: Drive train: full-time 4WD with 3 differentials (remote rear and center differential lock as standard equipment) Front suspension type: double a-arm IFS Rear suspension type: solid rear axle with 4-link suspension Scale: 1/5 Wheelbase: 565mm Front track width: 420mm Rear track width: 420mm Caster angle of kingpin: 20 degrees Front camber (adjustable): 3 degrees Toe-in (adjustable): 3 degrees Rear toe-in (not adjustable): 0 degrees Rear camber (not adjustable): 0 degrees Approach angle: about 90 degrees Departure angle: about 90 degrees Break-over angle: about 45 degrees Minimum turning radius: about 1.5 meters The maximum steering angle: about 30 degrees Maximum gradient: about 50 degrees Slide slope: about 40 degrees Maximum articulation: about 80 degrees (need to remove the front and rear anti-roll bars and loosen the angle limit screws of the front shock mounting beam) Lower trailing arm length (center/center of spherical bearings): 257 mm Chassis ground clearance (wheel diameter 230 mm): 115 mm Ground clearance under rear differential (wheel diameter 230 mm): 75 mm The maximum external dimensions of the vehicle body (length × width × height): 790 mm × 525 mm × 380 mm (with wheels of 230 mm diameter and 100 mm width) Gear ratio range: 9:1 to14.9:1 (The gear ratio can be changed by different gear set in the center gear box) Factory standard gear ratio: 14.9:1 Gear modulus: M1.5 Number of locking differentials: 2, servos for activation not included Locking differential positions: center and rear Wheel size: diameter 230 mm; width 100 mm. The tires feature Kevlar fiber belt to prevent ballooning and can handle 12S power Wheel drive size: 24 mm hex Front shocks mounting length (two-stage springs): 170 mm Front shock travel: 53 mm Rear shock mounting length (two-stage springs): 212mm Rear shock travel: 80 mm Calculated top speed: 8S power: 80 km/h (based on a 750KV motor) 12S power 110 km/h (based on a 680KV motor) (The maximum speed is calculated based on the electronic components and the actual numbers may vary) Weight of empty frame (excluding wheels and electronic components): 13.5 kg Total weight: approx. 22 kg Maximum payload of the frame: about 10 kg (do not press heavy objects or let people sit on the frame for driving operations, which may cause damage to parts) Lubricants parameters Front shock oil (silicone oil): 100cst Rear shock oil (silicone oil): 100cst Front differential oil (silicone oil): 300,000 cst Center differential oil (silicone oil): 300,000 cst Rear differential oil (silicone oil): 300,000 cst Front gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) Center gear box (grease): Swedish molybdenum disulfide high temperature grease (blue) Rear axle gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) (The above lubricants parameters are for reference only, and can be replaced according to your driving habits and environment) Frame materials and parts specifications, etc. Chassis Material: AL6061-T6 (aluminum) Processing technology: CNC machining, no stamp-out processing Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Front skid plate plate (standard configuration) Material: AL6061-T6 (aluminum) Processing technology: CNC machining non-casting Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Lower trailing arms Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: The thickness of the part is 30 mm Front gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specification: wall thickness 4 mm Center gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 2.5 mm Rear axle Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 4 mm Front spindles Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening C-Hubs Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening Differential ring and pinion (front and rear) Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Center gear box spur gears Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Differential spider gears Material: steel-based powder metallurgy Processing technology: hot isostatic pressing sintering Heat treatment process: vacuum Differential locking clutch Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Front suspension drive shaft (CVD structure at the wheel end, universal joint structure at the gear box end) Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: CVD end shaft diameter 12 mm; gearbox end universal joint maximum outer diameter 32mm Center drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specification: shaft diameter 12 mm Rear universal drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: The outer diameter of the spline telescopic shaft is 12 mm; the maximum diameter of the universal joint is 32 mm. Rear axle shafts Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: shaft diameter 12 mm, non-pin positive locking structure, shaft reaches into the differential planetary gear. Front bumper Material: high strength nylon Roll cage Material: high strength nylon Specification: diameter 10mm Car body shell Material: Polycarbonate Specifications: thickness 1.5 mm Original FG Monster Buggy body shell # 54150/01 with rear wing # 58150/02 Receiver box: nylon Front and rear shock absorption main parts Upper shock cap Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: anodizing Shock body Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: hard anodizing and hardening Specification: barrel diameter 28mm Shock spring Material: piano wire Surface treatment: black nickel plating Specification: front 2.8mm/rear 2.5mm Shock piston rod Material: high-strength carbon steel Processing technology: high precision grinding Heat treatment: carburizing and hardening Specification: diameter 8mm Spring perches Material: nylon Piston Material: nylon Processing technology: CNC machined, no injection molding Sealing ring Material: silicone Front shock mounting beam: AL6061-T6 (aluminum) Rear shock tower: AL6061-T6 (aluminum) Servo fixing frame: AL6061-T6 (aluminum) Steering rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Steering linkage rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Rear axle stabilizer bar Material: high-strength carbon steel Specification: 6 mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Ball heads Material: SUS304 stainless steel Specification: ball diameter 11 mm Front lower A-arm: high-strength nylon Center gear box mounts: AL6061-T6 (aluminum) Lower trailing arm brackets: AL6061-T6 (aluminum) Adjustable steering servo arm (comes as standard!): AL6061-T6 (aluminum) (adjustment angle 20 degrees) Wheels Specifications Diameter: 230 mm Width: 100 mm Hexagonal drive: 24 mm Material Rim: high-strength nylon Tire skin: natural rubber (Kevlar fiber belted) Liner: high elastic sponge Hex drive: The hex insert is powder steel metallurgy, and the outer reinforcement ring is SUS304 stainless steel All vehicle screws: 10.9 grade carbon steel General components: Wheels: Most 1/5 scale wheels with 24 mm hex drive and a diameter ranging from 190-230 mm and a width of 70-100 mm can be used. When the diameter is greater than 190 mm and the width is greater than 80 mm, the steering angle needs to be limited, and the steering angle has to be adjusted on the transmitter to about 75%. It is recommended to use wheels with a diameter of 230 mm and a width of 100 mm to maximize the performance and handling of the car. Differential spider gear assembly: HPI BAJA 5B compatible Nylon ball joints: 5ive-T size (ball diameter 11 mm) Electronic components configuration ESC Specification: 8S-12S Quantity: 1 Motor Specifications: market standard motor for 1/5 vehicles, such as 5692/56112/58113 When using 8S power, the motor KV value should be lower than 800. When using 12S power, the motor KV value should be lower than 600. When selecting a 12S motor, you should accurately consult whether it supports 12S power. Improper selection may cause serious damage to the motor. The diameter of the motor shaft is 8 mm, and the depth of the flat surface is 1 mm. The protruding length of the motor shaft should be greater than 20 mm and less than 40 mm. Quantity: 1 Battery 8S: 2 groups of 4S (6,000-12,000 mAh) in series 12S: 2 sets of 6S (6,000-12,000 mAh) in series When choosing a battery, it should be noted that the three-dimensional size of the two batteries together cannot be larger than the size of the battery compartment. Quantity: 2 packs Battery compartment size: length 193 mm×width 125 mm×height 100mm Steering servo: Specification (15T output shaft): 50-85 kg Use common 1/5 model servos (mounting bolt pattern 17.5 mm×75 mm). Quantity: 2 Differential lock servo Specification (25T output shaft): 15-35 kg Use common 1/8 model steering servos ( mounting bolt pattern 10.0 mm × 49.5 mm), it is recommended to use 25 kg steering gear, but it should not be stronger than 35kg, which may easily cause the displacement of the differential lock limiter and change the pulling stroke. The differential lock function fails. Quantity: 2 Remote control Type: car Channels: 5 channels or more (steering; throttle; differential lock uses two channels; car lighting (optional) channel) Quantity: one set Charger Type: Equipped with lithium battery balancing function Specifications: 4S or above Quantity: one set Battery safe storage container Common tools Tool type: Allen key wrench; Hex wrenches; circlip pliers Allen wrench Sizes (metric system): 1.5 mm; 2.0 mm; 2.5 mm; 3.0 mm; 4.0 mm; 5.0 mm Hex wrenches Sizes (metric system): 7 mm; 8 mm; 9 mm; 10 mm Circlip pliers Type: external circlip pliers (when gripping the handle of the circlip pliers, the front end should open outward) Specifications: The diameter of the tip is less than 1mm, and the use range is 4-10mm

Ghost Rabbit GR1 - the new 4WD metal model from UFRC incl. RTR equiptment! TT56112/520Top Tuning Monster Brushless Motor 520kV y1549 ZTW Beast Pro 300A 12S ESC 2x Voltmeter Spektrum DX5C Smart 5CH DSMR radio control incl. SPMSR515 receiver 2 pieces y1570 CYS S0650 large scale servo, 55 kg/0,11 sec for Steering 2 pieces y2009 Top Tuning Digital pro Servo 25 kg for Differential lock Required for completion: 2 pieces of 6S batteries with EC8 connectors (total max. size for both batteries combined: length 193 mm × width 125 mm × height 100 mm) Charger for LiPo batteries Its external dimensions are not much bigger than those of a 1/6 car, yet its wheelbase is on par with many 1/5 cars and it has no overhangs at all; its tires fit a monster truck (230 mm diameter!). This results in amazing handiness for a large scale car combined with outstanding off-road capability. The GR1 comes out of the box almost as an all-metal vehicle. Tuning parts to reinforce the model are no longer necessary. Center and rear differential come standard with mechanical locks which can be activated independently by the radio. Of course, a radio system with the appropriate number of channels is required to use this feature. The dimensioning of all parts is designed for great reliability, e.g. the ball joints in the lower trailing arms are standardized industrial swivel bearings with an inner diameter of 6 mm, and the driveline can handle 12S hands down. Oversized drive shafts also on the front axle are machined and hardened steel with fixed joints at both ends and sliding piece for length compensation. The tires feature a vulcanized fabric reinforcement made of Kevlar; ballooning is actually a thing of the past for them. Thanks to Kevlar, the fabric belt can be relatively thin, so the tires are soft and flexible despite the fabric. Aluminum servo arms for all 4 servos (steering and differential locks) are standard. The levers of the two steering servos are adjustable. Each steering servo has its own adjustable servo saver. A stainless steel adjustment tool is included. The Ackerman rod features four ball bearings. Shock absorbers with 8 mm piston rods and hard anodized shock bodies. All drive gears milled from steel and hardened. Two voltmeters can be optionally installed in the receiver box to monitor the traction batteries. The cage can be removed with only 4 clips, but even that is not a requirement for battery replacement. Ghost Rabbit GR1 (1/5 4WD solid rear axle)Main features of the 4WD Ghost Rabbit GR1: The strength of the components supports 12S power The wheelbase of 1/5 scale cars: 565mm The length of 1/6 scale cars: total length 790mm (when equipped with wheels with a diameter of 230mm) The whole car uses mostly metal parts, so there is no need to spend a lot of money on option parts later. The weight of the GR1 ready to run with 2x 6S/8.000 mAh batteries and 520KV motor is about 22 kg.But if you think now that this is a ponderous steamroller, you better think again. A "Tank on speed" is a better description. Despite the weight, wheelies can be called up at any time thanks to the appropriate gear reduction, even if the controller is only set to level two of four in acceleration (punch).At the same time, the possible twisting of the chassis is almost like that of a crawler. With the diff locks activated, the GR1 is almost unstoppable. Technical details: Drive train: full-time 4WD with 3 differentials (remote rear and center differential lock as standard equipment) Front suspension type: double a-arm IFS Rear suspension type: solid rear axle with 4-link suspension Scale: 1/5 Wheelbase: 565mm Front track width: 420mm Rear track width: 420mm Caster angle of kingpin: 20 degrees Front camber (adjustable): 3 degrees Toe-in (adjustable): 3 degrees Rear toe-in (not adjustable): 0 degrees Rear camber (not adjustable): 0 degrees Approach angle: about 90 degrees Departure angle: about 90 degrees Break-over angle: about 45 degrees Minimum turning radius: about 1.5 meters The maximum steering angle: about 30 degrees Maximum gradient: about 50 degrees Slide slope: about 40 degrees Maximum articulation: about 80 degrees (need to remove the front and rear anti-roll bars and loosen the angle limit screws of the front shock mounting beam) Lower trailing arm length (center/center of spherical bearings): 257 mm Chassis ground clearance (wheel diameter 230 mm): 115 mm Ground clearance under rear differential (wheel diameter 230 mm): 75 mm The maximum external dimensions of the vehicle body (length × width × height): 790 mm × 525 mm × 380 mm (with wheels of 230 mm diameter and 100 mm width) Gear ratio range: 9:1 to14.9:1 (The gear ratio can be changed by different gear set in the center gear box) Factory standard gear ratio: 14.9:1 Gear modulus: M1.5 Number of locking differentials: 2, servos for activation not included Locking differential positions: center and rear Wheel size: diameter 230 mm; width 100 mm. The tires feature Kevlar fiber belt to prevent ballooning and can handle 12S power Wheel drive size: 24 mm hex Front shocks mounting length (two-stage springs): 170 mm Front shock travel: 53 mm Rear shock mounting length (two-stage springs): 212mm Rear shock travel: 80 mm Calculated top speed: 8S power: 80 km/h (based on a 750KV motor) 12S power 90 km/h (based on a 520KV motor) (The maximum speed is calculated based on the electronic components and the actual numbers may vary) Weight of empty frame (excluding wheels and electronic components): 13.5 kg Total weight: approx. 22 kg Maximum payload of the frame: about 10 kg (do not press heavy objects or let people sit on the frame for driving operations, which may cause damage to parts) Lubricants parameters Front shock oil (silicone oil): 100cst Rear shock oil (silicone oil): 100cst Front differential oil (silicone oil): 300,000 cst Center differential oil (silicone oil): 300,000 cst Rear differential oil (silicone oil): 300,000 cst Front gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) Center gear box (grease): Swedish molybdenum disulfide high temperature grease (blue) Rear axle gearbox (grease): Swedish molybdenum disulfide high temperature grease (blue) (The above lubricants parameters are for reference only, and can be replaced according to your driving habits and environment) Frame materials and parts specifications, etc. Chassis Material: AL6061-T6 (aluminum) Processing technology: CNC machining, no stamp-out processing Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Front skid plate plate (standard configuration) Material: AL6061-T6 (aluminum) Processing technology: CNC machining non-casting Surface treatment: hard anodizing and hardening Specifications: thickness 5 mm Lower trailing arms Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: The thickness of the part is 30 mm Front gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specification: wall thickness 4 mm Center gear box housing Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 2.5 mm Rear axle Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: anodizing Specifications: wall thickness 4 mm Front spindles Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening C-Hubs Material: AL6061-T6 (aluminum) Processing technology: CNC machining Surface treatment: hard anodizing and hardening Differential ring and pinion (front and rear) Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Center gear box spur gears Material: high-strength billet gear steel, non-powder metallurgy Processing technology: CNC gear hobbing machine Heat treatment process: carburizing and hardening Modulus: M1.5 Differential spider gears Material: steel-based powder metallurgy Processing technology: hot isostatic pressing sintering Heat treatment process: vacuum Differential locking clutch Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Front suspension drive shaft (CVD structure at the wheel end, universal joint structure at the gear box end) Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: CVD end shaft diameter 12 mm; gearbox end universal joint maximum outer diameter 32mm Center drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specification: shaft diameter 12 mm Rear universal drive shaft Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: The outer diameter of the spline telescopic shaft is 12 mm; the maximum diameter of the universal joint is 32 mm. Rear axle shafts Material: high-strength billet carbon steel Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Specifications: shaft diameter 12 mm, non-pin positive locking structure, shaft reaches into the differential planetary gear. Front bumper Material: high strength nylon Roll cage Material: high strength nylon Specification: diameter 10mm Car body shell panels Material: Polycarbonate Specifications: thickness 1.5 mm Clear Receiver box: nylon Front and rear shock absorption main parts Upper shock cap Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: anodizing Shock body Material: AL6061-T6 (aluminum) Processing technology: CNC Surface treatment: hard anodizing and hardening Specification: barrel diameter 28mm Shock spring Material: piano wire Surface treatment: black nickel plating Specification: front 2.8mm/rear 2.5mm Shock piston rod Material: high-strength carbon steel Processing technology: high precision grinding Heat treatment: carburizing and hardening Specification: diameter 8mm Spring perches Material: nylon Piston Material: nylon Processing technology: CNC machined, no injection molding Sealing ring Material: silicone Front shock mounting beam: AL6061-T6 (aluminum) Rear shock tower: AL6061-T6 (aluminum) Servo fixing frame: AL6061-T6 (aluminum) Steering rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Steering linkage rods Material: high-strength carbon steel Specification: 6mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Rear axle stabilizer bar Material: high-strength carbon steel Specification: 6 mm Processing technology: CNC Heat treatment process: carburizing and hardening Surface treatment: electroplating Ball heads Material: SUS304 stainless steel Specification: ball diameter 11 mm Front lower A-arm: high-strength nylon Center gear box mounts: AL6061-T6 (aluminum) Lower trailing arm brackets: AL6061-T6 (aluminum) Adjustable steering servo arm (comes as standard!): AL6061-T6 (aluminum) (adjustment angle 20 degrees) Wheels Specifications Diameter: 230 mm Width: 100 mm Hexagonal drive: 24 mm Material Rim: high-strength nylon Tire skin: natural rubber (Kevlar fiber belted) Liner: high elastic sponge Hex drive: The hex insert is powder steel metallurgy, and the outer reinforcement ring is SUS304 stainless steel All vehicle screws: 10.9 grade carbon steel General components: Wheels: Most 1/5 scale wheels with 24 mm hex drive and a diameter ranging from 190-230 mm and a width of 70-100 mm can be used. When the diameter is greater than 190 mm and the width is greater than 80 mm, the steering angle needs to be limited, and the steering angle has to be adjusted on the transmitter to about 75%. It is recommended to use wheels with a diameter of 230 mm and a width of 100 mm to maximize the performance and handling of the car. Differential spider gear assembly: HPI BAJA 5B compatible Nylon ball joints: 5ive-T size (ball diameter 11 mm) Electronic components configuration ESC Specification: 8S-12S Quantity: 1 Motor Specifications: market standard motor for 1/5 vehicles, such as 5692/56112/58113 When using 8S power, the motor KV value should be lower than 800. When using 12S power, the motor KV value should be lower than 600. When selecting a 12S motor, you should accurately consult whether it supports 12S power. Improper selection may cause serious damage to the motor. The diameter of the motor shaft is 8 mm, and the depth of the flat surface is 1 mm. The protruding length of the motor shaft should be greater than 20 mm and less than 40 mm. Quantity: 1 Battery 8S: 2 groups of 4S (6,000-12,000 mAh) in series 12S: 2 sets of 6S (6,000-12,000 mAh) in series When choosing a battery, it should be noted that the three-dimensional size of the two batteries together cannot be larger than the size of the battery compartment. Quantity: 2 packs Battery compartment size: length 193 mm×width 125 mm×height 100mm Steering servo: Specification (15T output shaft): 50-85 kg Use common 1/5 model servos (mounting bolt pattern 17.5 mm×75 mm). Quantity: 2 Differential lock servo Specification (25T output shaft): 15-35 kg Use common 1/8 model steering servos ( mounting bolt pattern 10.0 mm × 49.5 mm), it is recommended to use 25 kg steering gear, but it should not be stronger than 35kg, which may easily cause the displacement of the differential lock limiter and change the pulling stroke. The differential lock function fails. Quantity: 2 Remote control Type: car Channels: 5 channels or more (steering; throttle; differential lock uses two channels; car lighting (optional) channel) Quantity: one set Charger Type: Equipped with lithium battery balancing function Specifications: 4S or above Quantity: one set Battery safe storage container Common tools Tool type: Allen key wrench; Hex wrenches; circlip pliers Allen wrench Sizes (metric system): 1.5 mm; 2.0 mm; 2.5 mm; 3.0 mm; 4.0 mm; 5.0 mm Hex wrenches Sizes (metric system): 7 mm; 8 mm; 9 mm; 10 mm Circlip pliers Type: external circlip pliers (when gripping the handle of the circlip pliers, the front end should open outward) Specifications: The diameter of the tip is less than 1mm, and the use range is 4-10mm