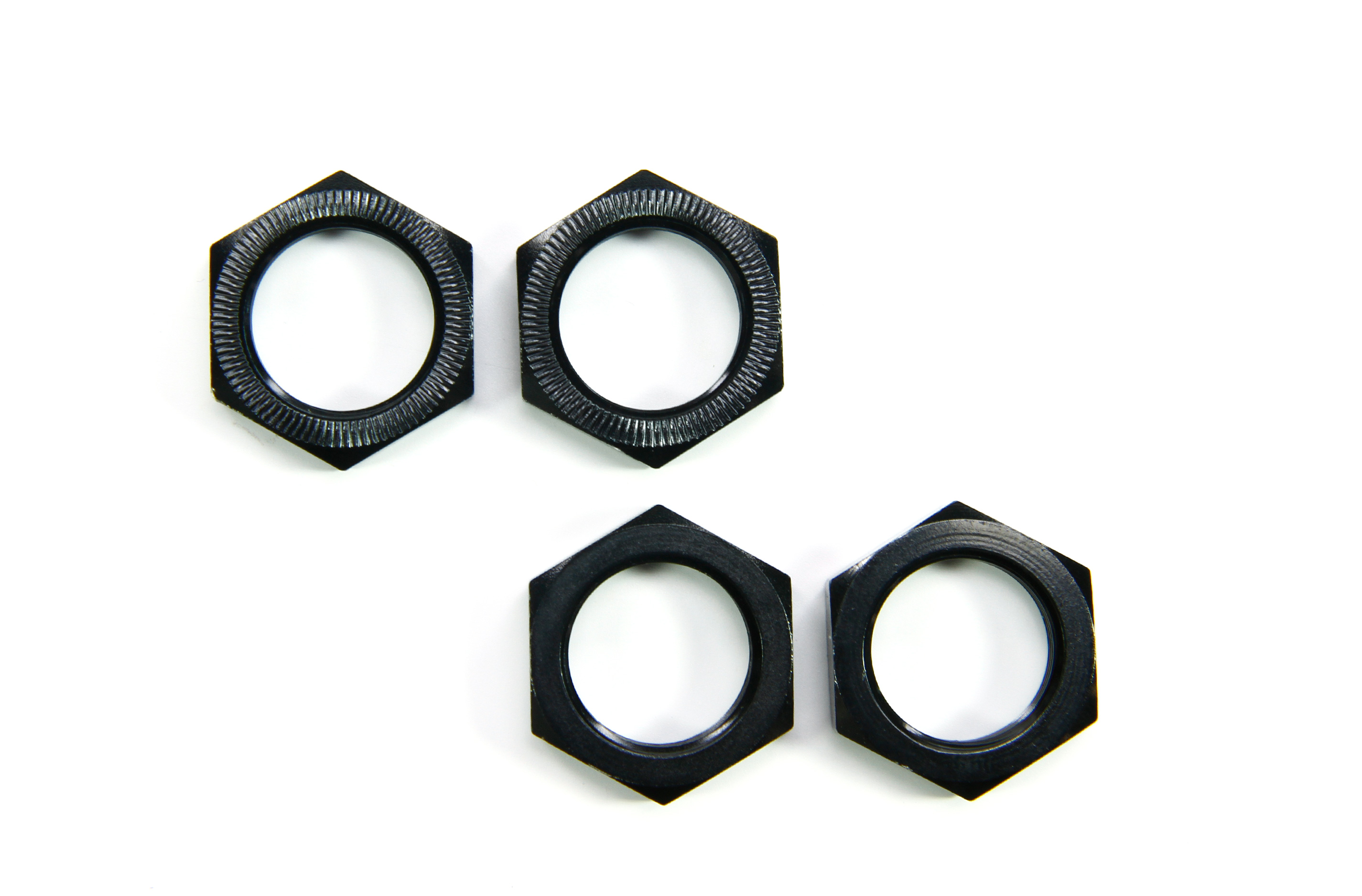

DBXL024 ATOP Aluminum axle extenders all Losi DBXL / DBXL-E / 2.0 / MTXL, with closed nuts

€64.90

Currently unavailable

Product number:

at_dbxl024

EAN:

4058575142843

Product information "DBXL024 ATOP Aluminum axle extenders all Losi DBXL / DBXL-E / 2.0 / MTXL, with closed nuts"

Genuine ATOP spare/option part.

CNC-machined from 6061-T6 aluminum by ATOP RC.

Increases track width by 25 mm. Fits all versions of DBXL / DBXL-E / 2.0 (brushless and gas) and MTXL. 2 mm O-rings protect against drive pin loss.

Set of four including O-rings, drive pins and closed wheel nuts (wrench size 24 mm!).

Contents:

CNC-machined from 6061-T6 aluminum by ATOP RC.

Increases track width by 25 mm. Fits all versions of DBXL / DBXL-E / 2.0 (brushless and gas) and MTXL. 2 mm O-rings protect against drive pin loss.

Set of four including O-rings, drive pins and closed wheel nuts (wrench size 24 mm!).

Contents:

- 1 set

Login

No reviews found. Share your insights with others.