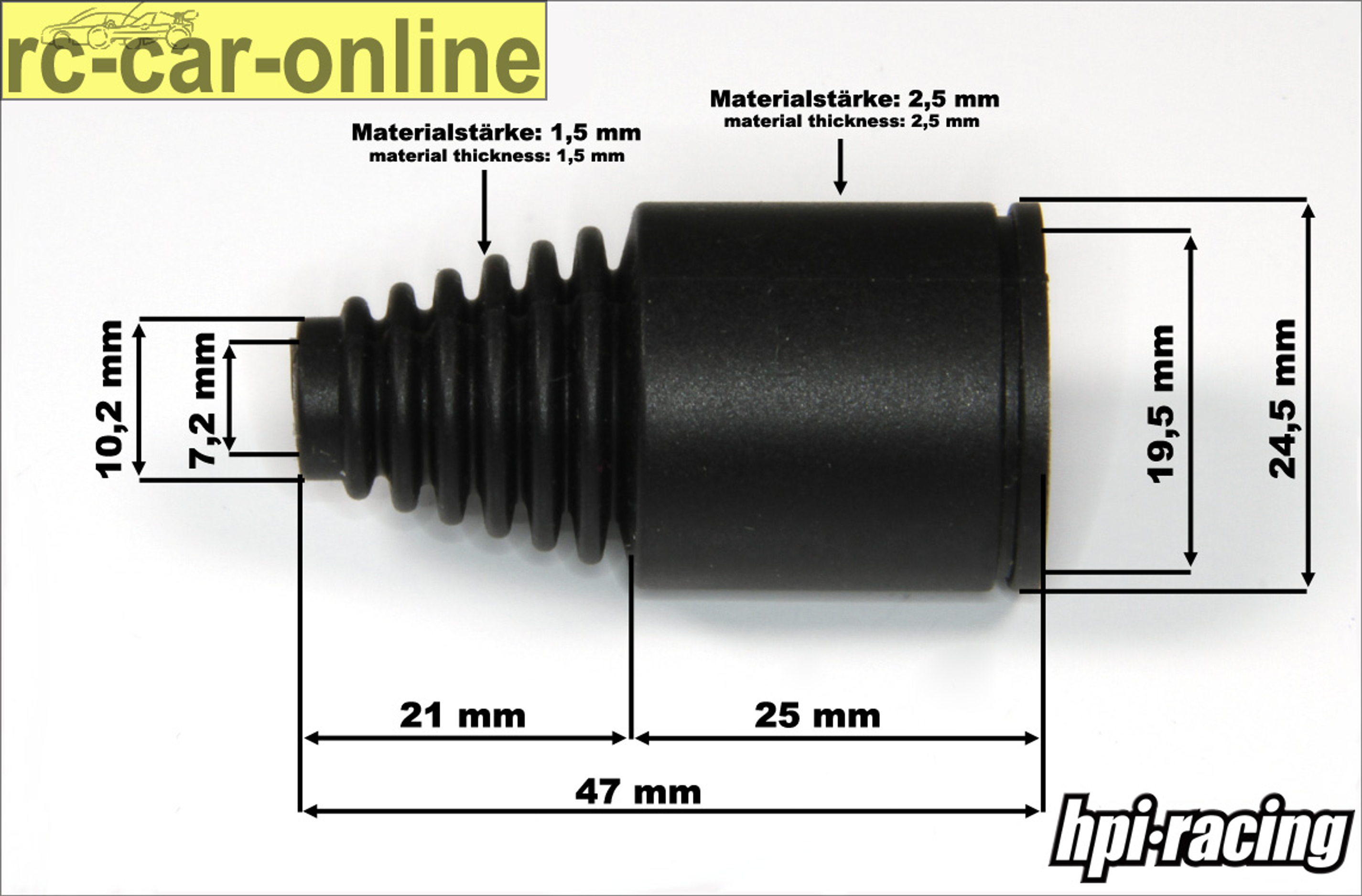

y86479 HighElastic driveshaft boots 47 mm, choice of colors, 4 pcs.

€12.90

Available

Product information "y86479 HighElastic driveshaft boots 47 mm, choice of colors, 4 pcs."

Available in the following colors:

- y86479/01 - black

- y86479/02 - red

- y86479/03 - orange

Contents:

- 4 pieces

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Accessories / Spare parts

Genuine HT spare/option part. The best solution for drive shaft positioning, can be used with ball drives or regular "dog bones" as well.The springs will be simply inserted into the drive cups.DImensions:Diameter: 11 mmHeight: 8 mmContents:4 piece

Customers also bought

Fits losi 5ive-T. Dimensions grommet:total length: 53 mm, down to 38 mm compressibleinner diameter: shaft 6 mm, shaft intake 19 mm Dimensions clamping ring: RW 20 galvanized, burnished for 20mm grommets Set content:Five x grommetTen x claming ring

Genuine HT spare/option part. New billet version, CNC-machined!Fits Zenoah G230/240/260/270/290/320, Losi, HPI Fuelie and CY engines. Not as easily damaged as the stock plastic unit.Does not fit PT (Carson/Smartech) engines!Contents:1 piece

Genuine HT spare/option part. Especially for CY / Zenoah G230/240/260/270/290/320, HPI and Losi engines.Can be used for removal of the standard clutch as well!Contents:1 piece

Genuine HPI spare/option part. Contents:1 set

Customers also viewed

Highly flexible driveshaft boots, equivalent to HPI part # H86479.Available in the following colors:y86479/01 - blacky86479/02 - redy86479/03 - orangeContents:4 pieces

Fits losi 5ive-T. Dimensions grommet:total length: 53 mm, down to 38 mm compressibleinner diameter: shaft 6 mm, shaft intake 19 mm Dimensions clamping ring: RW 20 galvanized, burnished for 20mm grommets Set content:Five x grommetTen x claming ring

Genuine HT spare/option part. Protect ball drive as well as cardan drive against dirt. For FG and Carson ball drives, fits standard dogbones as well.Contents:2 pieces

Genuine HT spare/option part. Protect ball drive as well as cardan drive against dirt.For FG and Carson ball drives, fits standard dogbones as well.Content10 pieces

Genuine Carson spare/option part. Contents:4 piece

Genuine HT spare/option part. After-Run is a performance enhancing preservation, which ensures that the engine starts properly, even after a long time (winter break) storage. Added to the fuel it keeps the fuel system clean.Among other After-Run conserves the diaphragm of the Walbro carburetor!For long term storage (i.e. during winter!) "vital" for the carburetor diaphragms!For 23 to 32 cm³ engines like Zenoah, Chung Yang, PT, Losi, HPI a.s.o.It binds water in the fuel, particularly important when the engine is not run regularly or after wet races. After-Run improves engine performance, ensures better combustion, removes debris and residues. Simply add the content of the bottle to 5 litres of fuel.Contents:1 piece / 20 ml

Content: 20 Milliliter (€495.00 / 1000 Milliliter)