y0711/01 Single-sided split alloy servoarm for Savöx SV-0236MG, Rhino and 805er Servo

€16.90

% €18.90 (10.58% saved)

Available

Product information "y0711/01 Single-sided split alloy servoarm for Savöx SV-0236MG, Rhino and 805er Servo"

Suitable for all servos with an output shaft with 15 tooth spline shaft, for example:

- Multiplex Rhino

- Hitec 805

- Savöx SV-0236MG

- LOSB 0886 S901T (Original Losi 5ive-T throttle Servo servo)

- LOSB 0884 S900S (Original Losi 5ive-T steering servo)

- and many more!

- holes for linkage with M3 thread

When you count the teeth of your servo you can check if this alloy arm will fit to your servo.

Alloy servoarms are indispensable by strong digital servos, as used on big scale models for example, to optimize the servo forces being transferred.

Content:

- 1 pieces

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Alternatives

Splitted Alloy servoarm for a more protecting screw connection (with a 2,0 mm allen head screw driver) causing stiffness on the servo output shaftSuitable for all servos with an output shaft with 15 tooth spline shaft, for example:Multiplex RhinoHitec 805Savöx SV-0236MGLOSB 0886 S901T (Original Losi 5ive-T throttle Servo servo)LOSB 0884 S900S (Original Losi 5ive-T steering servo)and many more!holes for linkage with M3 threadWhen you count the teeth of your servo you can check if this alloy arm will fit to your servo. Alloy servoarms are indispensable by strong digital servos, as used on big scale models for example, to optimize the servo forces being transferred.Content:1 pieces

Accessories / Spare parts

Top quality spare tips, 2.5 mm.Fits GPM-Roadtech handles from screw driver set y0600. 1 piece

Top quality spare tips, 3.0 mm.Fits GPM-Roadtech handles from screw driver set y0600.

Customers also bought

Splitted Alloy servoarm for a more protecting screw connection (with a 2,0 mm allen head screw driver) causing stiffness on the servo output shaftSuitable for all servos with an output shaft with 15 tooth spline shaft, for example:Multiplex RhinoHitec 805Savöx SV-0236MGLOSB 0886 S901T (Original Losi 5ive-T throttle Servo servo)LOSB 0884 S900S (Original Losi 5ive-T steering servo)and many more!holes for linkage with M3 threadWhen you count the teeth of your servo you can check if this alloy arm will fit to your servo. Alloy servoarms are indispensable by strong digital servos, as used on big scale models for example, to optimize the servo forces being transferred.Content:1 pieces

Genuine FG spare/option part. Wide Off-Road Buggy tires 80mm, ready glued on rims. Suitable for all 1:6 Off-Road Buggies. To mount them on FG Off-Road models you need the 18 mm square wheel driver y6106/01. Due to the high torque load on the bonding of tires on largescale cars, checking the bonding from time to time and re-glueing (y0067) if necessary is unavoidable.Dimensions:Diameter: 180 mmWidth: 80 mmContent:2 pieces

Narrow Off-Road Buggy tires 60 mm, ready glued on rims. Suitable for all 1:6 Off-Road Buggies. To mount them on FG Off-Road models you need the 18 mm square wheel driver y0067. Due to the high torque load on the bonding of tires on largescale cars, checking the bonding from time to time and re-glueing () if necessary is unavoidable.Diameter: 180 mmWidth: 60 mmContents:2 pieces

This air filter oil is designed for lubricating foam filters for on-road and off-road use. It reinforces the filters' efficiency for better carburation and retains dirt, mud and sand particles. Prevents water from penetrating into the filter.It is recommended to put the filter with a little bit oil in a small polybag and work it vigorously by hand. Excessive oil must be pressed out (don't wring the foam!) afterwards.For cleaning the filter please use the special foam cleaner y0523.The filter element must be dry before re-oiling.Content:50 ml

Content: 50 Milliliter (€119.00 / 1000 Milliliter)

Customers also viewed

This pair of Tyres have the following use indications: GOOD GRIP situation for clean track. GOOD GRIP situation for medium asphalt. GOOD GRIP situation for medium temperatures. This pair of Tyres have the following technical features: REVO treated profile for the maximum traction and the maximum lateral grip. Treated profile studied to maintain the tyre surface alway clean from rubber murble. Compound exclusively developped for model tyres. Inside belt flexible but very strong, vulcanized directly together with tyre compound. Insert foam with special material for high temperatures, for maximum stability and high drive precision. Spoked wheel moulded with special material for high temperatures for maximum grip and stability. Special gluing system 100% guaranteed.The main sizes for this tyre are: WHEEL fixing with square 18mm. TYRE outside diameter 118mm. WHEEL inside diameter 90mm. TYRE tota width 65mm. Note:The harder a tire compound - the longer it lasts, but the more moderate the performance.The softer a tire compound - the better the performance, but the lower the durability. Hint!As a rule, the same tires can be used for front and rear.If the vehicle tends to oversteer, this can be avoided by using a harder front tire!In wet conditions you should use a rain tire which offers maximum grip under these circumstances.With the use of Magic Rain, a tire traction compound, the grip can be further improved.Check your tires after driving! It can happen that a tire starts to detach from the rim, in this case you should glue this spot immediately with our tire repair kit (y0067), otherwise the tire could detach completely from the rim.So find out which tire is the best for you!

The Sportsline quality at a reasonable price for beginners. For rookies and all those who simply just want to have fun and drive a DTM Audi, Mercedes or a fast Porsche. The Sportsline series is ideal for car modellers whose main focus is not just the chassis, but rather the combination of chassis and body shell.Technical description:The model has a 510 wheelbase. The models are built on a 4mm alloy chassis with double wishbones at front and rear axle. All borings of the alloy chassis are countersunk to prevent the screw heads from bearing out. The models are serial equipped with the 2-damper front axle which guarantees an optimal traction of both front wheels. At the front/rear axle you can adjust through track rods or adjusting screws with right-/left-handed thread the king pin angle, trailing effect and toe-in. Further equipment points are front disk brakes, differential gear, easy-running FG ball drive, alloy brake calliper with big brake disk, stabilizer bar front and rear, tuned pipe muffler, Evo gas tank, rear brace, 24T steel pinion, spark plug cap suppression cover, latest version (Evo) oil-pressure shock absorbers with volume control and external adjusting ring for the initial spring preload. All rotating parts as shafts, axles and clutch bells a.s.o. are supported by ball bearings. You can select the car with complete RTR-equipment from the options menu. RTR-equipment RTR = Ready to Run. The RTR version comes ready to use with the 2,4 GHz rc-system already installed. Transmitter 2,4 GHzReceiverHigh power servo for throttle and brakeLargescale servo for steeringTx-battery, rx-battery The models are equipped with a powerful 23ccm combustion engine. The engine needs a 2-stroke petrol oil mixture. One tank filling gives you about 45 minutes driving fun. The power is transmitted over the well-tried system: from the engine over the 2-block clutch over radial tooth wheels on to the rear axle which is equipped with the bevel differential gear with pluggable axles. RC-plate with receiver box.To complete the models all merchantable servos and radio control systems are suitable. The RTR version comes with complete factory installed rc-system, including Ni-Cads! The car comes with an unpainted body shell.Dimensions: Length: 780 mm Width: 405 mm Height: 250 mm Wheelbase: 510 mm HT-Edition? HT-Edition means: this version comes with a big set of spare / option parts included. Steel pinions - Non-standard sizesEach of two different ratios are supplied with.Modul: m=1,5Value: 62,60 EURAlloy engine mount bigCNC machined alloy engine mount, direkt replacement for the stock plastic part, heat and tweak resistant. They come with all necessary hardware included. Value: 64,95 EUR Alloy spur gear carrierUse for 39T - 44 teeth spur gears.Value: 39,90 EUR Ball bearing set, sealed, set of 14The seal rings on sealed ball bearings keep dirt and dust out of the bearings. They are therefore particularly suitable for use in dirty and dusty environments.Value: 59,90 EURTotal value: 227,35 EURTouring cars in action!Painting tips:

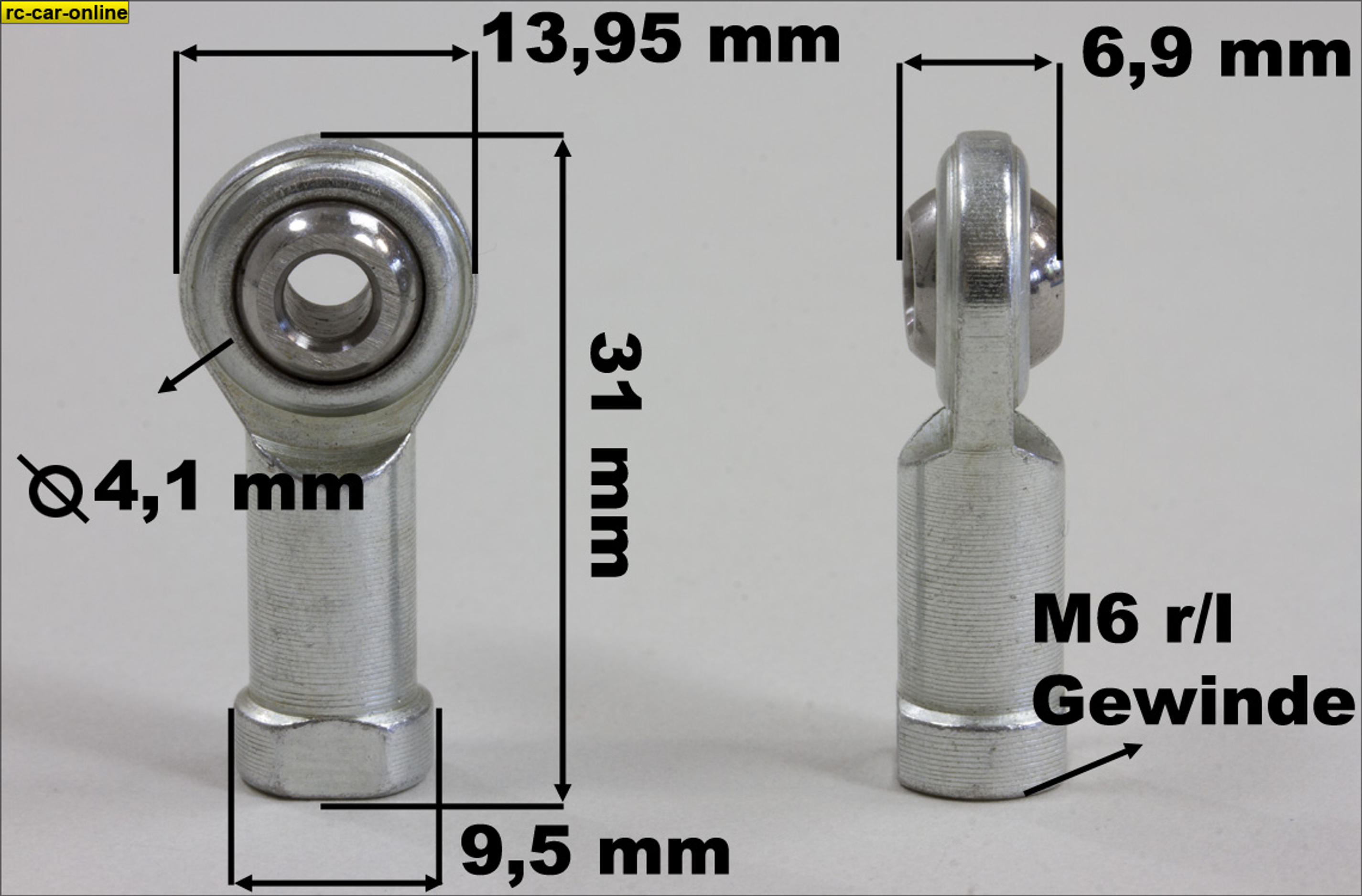

Steel ball joint 6 mm r/h or l/h thread, 4 mm bore in ball, for steering rods and other applications.This version is for steering rod applications.Sets available:One each with r/h and l/h threadOne x r/h threadOne x l/h thread Please note:We recommend using a nut 4472/03 for locking the r/h thread ball joint to prevent the linkage from loss of adjustment.

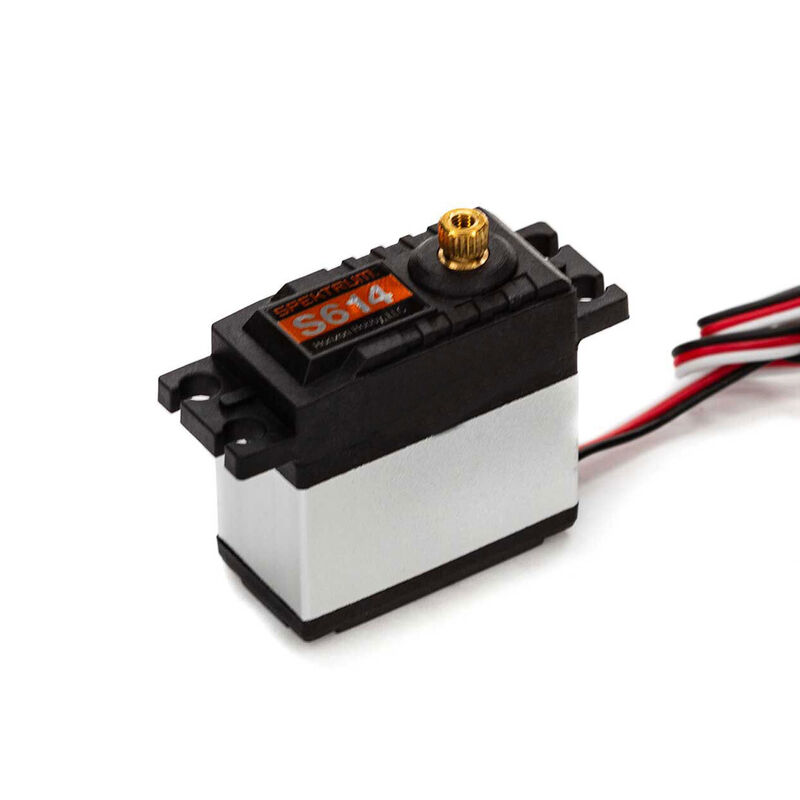

S614 Waterproof Metal Gear Surface Servo, 23T ProduktspezifikationenAnwendung : OberflächeBearing : DualBuchse oder KugellagerlagerConnector Wire Length 10.4" (264 mm)Eingangsspannung 6.0VGetriebeart : MetallGetriebematerial : BronzeMaximum Servo Torque 201.4oz-in (14.5kg-cm) at 6.0VMotortyp : BürstenmotorProduct Height(Länge) 1.6" (41 mm)Product Length(Höhe) 1.8" (46 mm)Product Weight(Gewicht)2.2 oz (62g)Product Width(Breite) 0.8" (20 mm)Programmierbar : Nein(No)Servo Betriebsspannung 6.0VServo Größenkategorie StandardServo Typ : DigitalSpline Count : 23 - Tooth(Zähne)Überladeschutz : Nein(No)Verbindertyp : UniversalWasserabweisend : Ja(Yes)1 Stück(piece)

CNC-machined from 6061-T6 aluminum by Area RC, significantly stronger and more rigid than any plastic version. The length of the arm is 43 mm. AREA-XL BJ032/01 with 23 teeth, red for KO PRO, JR, Sanwa, Airtronics- and many other Servos with 23 teeth shaft

Splitted Alloy servoarm for a more protecting screw connection (with a 2,0 mm allen head screw driver) causing stiffness on the servo output shaftSuitable for all servos with an output shaft with 15 tooth spline shaft, for example:Multiplex RhinoHitec 805Savöx SV-0236MGLOSB 0886 S901T (Original Losi 5ive-T throttle Servo servo)LOSB 0884 S900S (Original Losi 5ive-T steering servo)and many more!holes for linkage with M3 threadWhen you count the teeth of your servo you can check if this alloy arm will fit to your servo. Alloy servoarms are indispensable by strong digital servos, as used on big scale models for example, to optimize the servo forces being transferred.Content:1 pieces

Genuine FG spare/option part.Spare/option part for the FW01.Contents:1 set