DBXL023/3 ATOP Aluminum/steel differential case for DBXL/XL-E/XL-E 2.0, set of 3

€149.90

Currently unavailable

Product number:

at_dbxl023_3

EAN:

4058575143444

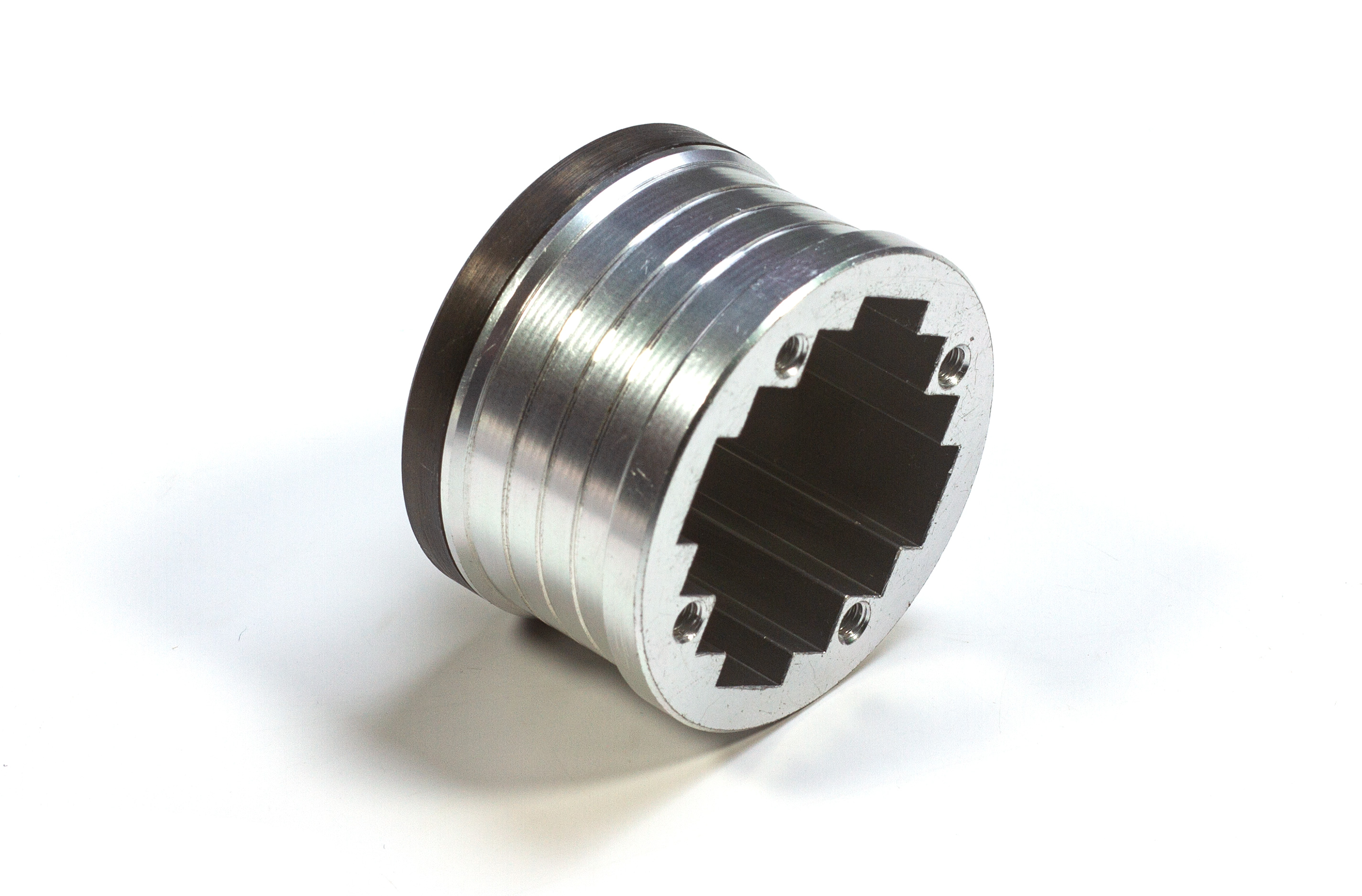

Product information "DBXL023/3 ATOP Aluminum/steel differential case for DBXL/XL-E/XL-E 2.0, set of 3"

Genuine ATOP spare/option part.

Two-part differential housing made of aluminum with steel bearing shield. The one-piece steel end shield ensures greater stability compared to aluminum end shields with a pressed-in bushing.

Fits all differentials in all DBXL and DBXL-E 2.0 versions!

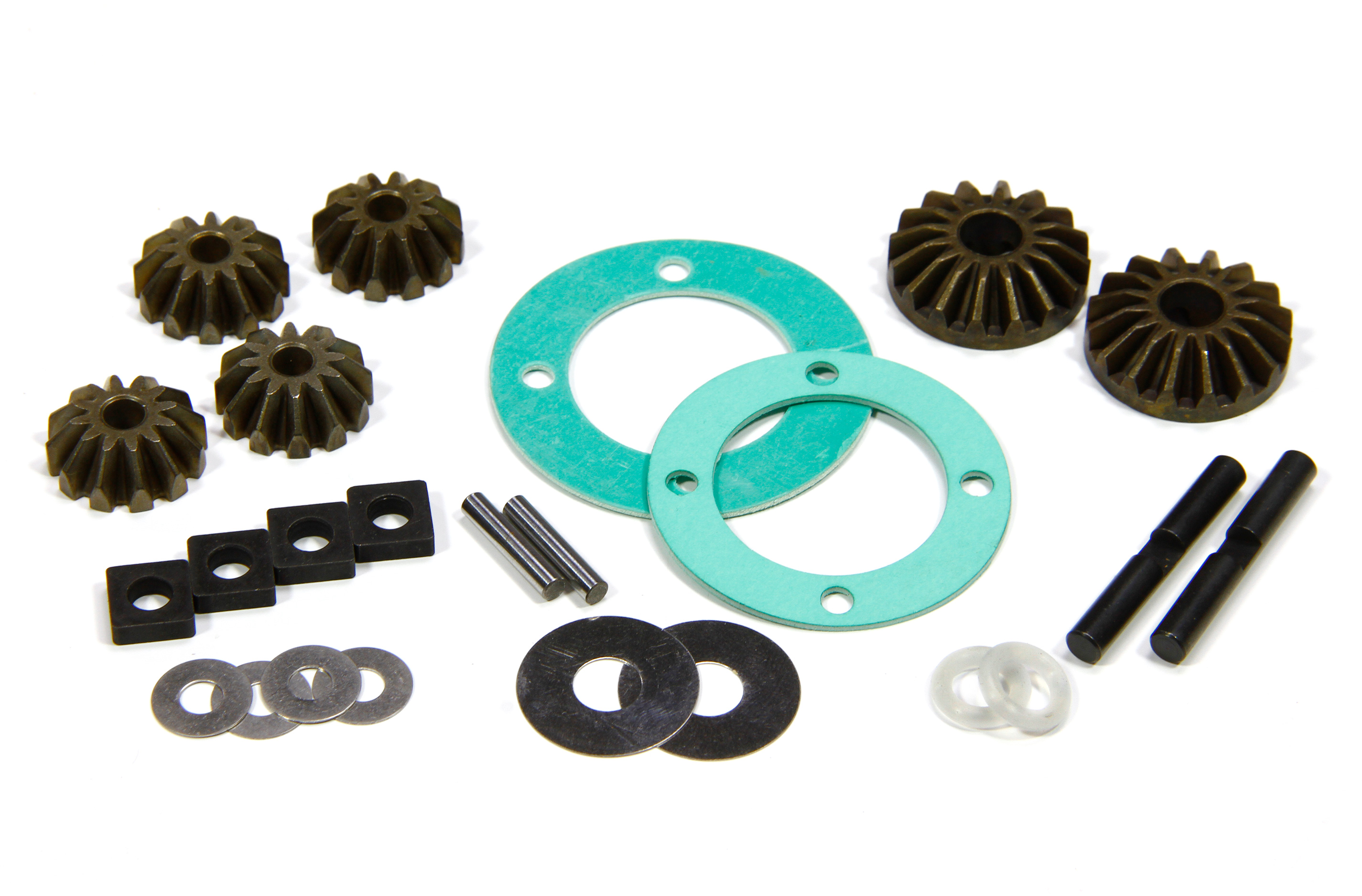

The delivery includes gaskets and O-rings, screws, ball bearing and sliding blocks.

Contents:

Set of 3!

Two-part differential housing made of aluminum with steel bearing shield. The one-piece steel end shield ensures greater stability compared to aluminum end shields with a pressed-in bushing.

Fits all differentials in all DBXL and DBXL-E 2.0 versions!

The delivery includes gaskets and O-rings, screws, ball bearing and sliding blocks.

Contents:

- 3 pieces

Login

No reviews found. Share your insights with others.