7341/08 FG Fan cover A for Zenoah

€47.50

Available

Product number:

fg_7341_08

EAN:

3410564517208

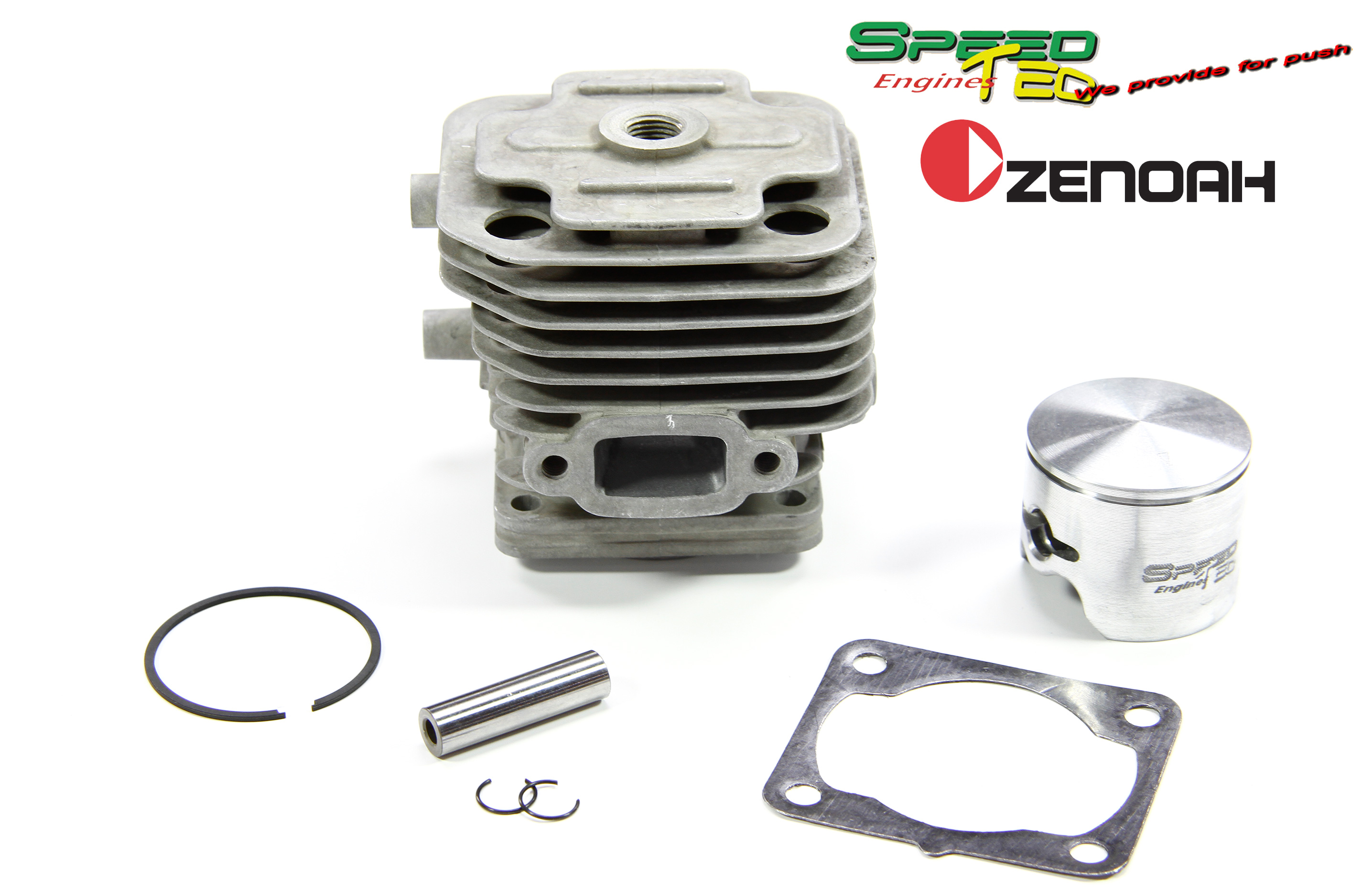

Product information "7341/08 FG Fan cover A for Zenoah"

Genuine FG spare/option part.

For Zenoah G230/240/260/270/290

Contents:

For Zenoah G230/240/260/270/290

Contents:

- 1 piece

Login

No reviews found. Share your insights with others.