1100 Samba Formel 1 tuned pipe for FG, Harm and Genius

€239.90

Currently unavailable

Product information "1100 Samba Formel 1 tuned pipe for FG, Harm and Genius"

Fits FG cars only in combination with a body shell from Samba or Lightscale!

Our unique design for Formula 1 cars. The outlet tube is pointing under the car.

B.I. is standing for Blown In. Best to use with the Moca F1 Carbon diffusor

Contents:

- 1 piece

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Customers also viewed

The Samba 7 titanium gives you a weight saving of 140 grams compared to the steel version. We have tested and optimized the Samba 7 Titan- tuned pipe system for half a year on the engine dyno and an additional three months on various racetracks! The pipe has a new, very strong connection system. This low-maintenance flexible connection between pipe and manifold is secured by four (!) springsDespite of the increased performance fuel consumption remains the same compared to a Samba 6 pipe. The Samba 7 system provides significantly better performance, i.e. the power is optimally available across the engines entire rpm range! New New connection from exhaust to manifold Lower center of gravity through new alignment Also suitable for 510 wheelbaseSamba 7 can also be installed in cars equipped with Magura 2 hydraulic brakes (see pictures).Of course, the Samba 7 tuned pipe system is race legal for racing, with the DMC approval number 50-1101 engraved. The Samba 7 - tuned pipe system comes with an installation kit.Fits: All On-road cars from FGContrastBergonzoniHarmGeniusand many others as well<Will fit medium (510 mm) wheelbase cars from FG as wellOriginal statement from Samba: "This new tuned pipe system is the result of the development"

We have tested and optimized the Samba 8 tuned pipe system for half a year on the engine dyno and an additional three months on various racetracks! The pipe has a new, very strong connection system. This low-maintenance flexible connection between pipe and manifold is secured by four (!) springsDespite of the increased performance fuel consumption remains the same compared to a Samba 7 pipe. The Samba 8 system provides significantly better performance, i.e. the power is optimally available across the engines entire rpm range! Again and again, podium places are achieved at major events through the use of Samba tuned pipe systems.Of course, the Samba 8 tuned pipe system is race legal for racing, with the DMC approval number 10-1504 engraved. The Samba 8 - tuned pipe system comes with an installation kit. The mounting pictures shows the Samba 8 in Titan version.Original statement from Samba: "This new tuned pipe system is the result of the development of the Samba 7 tuned pipe!"

26 cm³ Zenoah engine for large scale cars!Please note: contrary to their new designation the displacement has not been increased! The outer dimension didn't change, so you don't need any additional parts for the engine swap!The engines feature the following improvements over their G260RC:Quantity of cylinder mounting bolts increased from 2 to 4Improved strength of crankcaseAdded additional bearing on the PTO (clutch) side of crankshaftRedesigned shape of cylinder finsDimension of air intake port is 5% widerNew carburetor (WT-990) Contains internal fuel pump which increases acceleration from idle to wide open throttle.Removal of choke valve increases performance by increasing air flow to the carburetor Changed material of the insulator gasket to metal, which improves sealing performanceThe engine will be delivered with pull starter, carb and spark plug / spark plug cap. Genuine Zenoah air filter and / or complete clutch and / or ball beard carburetor are optionally available at additional charge. Compatibility Zenoah / Losi 5ive-T:Please note that for installation in a Losi 5ive the fan cover must be swapped for a Losi or CY cover #5341 in order to fit the chassis" bolt pattern.If you want to install a Zenoah engine into the Losi 5ive, you usually have to use a fan cover from the CY engine.However, there is a workaround to maintain Zenoah fan cover.The adjustment is done via the pinion specific mounting plates for the engine. The change always affects only the rear, outer (carburetor side) plate under the fan cover. This is rotated by 180°; so that the embossed number on this plate faces the exhaust side of the engine!18T pinion: use 20T plate, rotated 180°19T pinion: use 19T plate, rotated 180°20T pinion: use 18T plate, rotated 180°On the plus side you gain the opportunity to easily mount a Zenoah engine keeping the original fan cover. On the other hand there will be the disadvantage of the necessity to combine two different sets of engine mounting plates when installing any pinion other than the stock 19T version. Therefore we do not recommend this workaround for everyday use. Nevertheless it works perfectly should ever the need arise. Attention! We recommend to run exclusively fully synthetic 2-stroke engine oil, like y0813 Motul 800 racing oil.

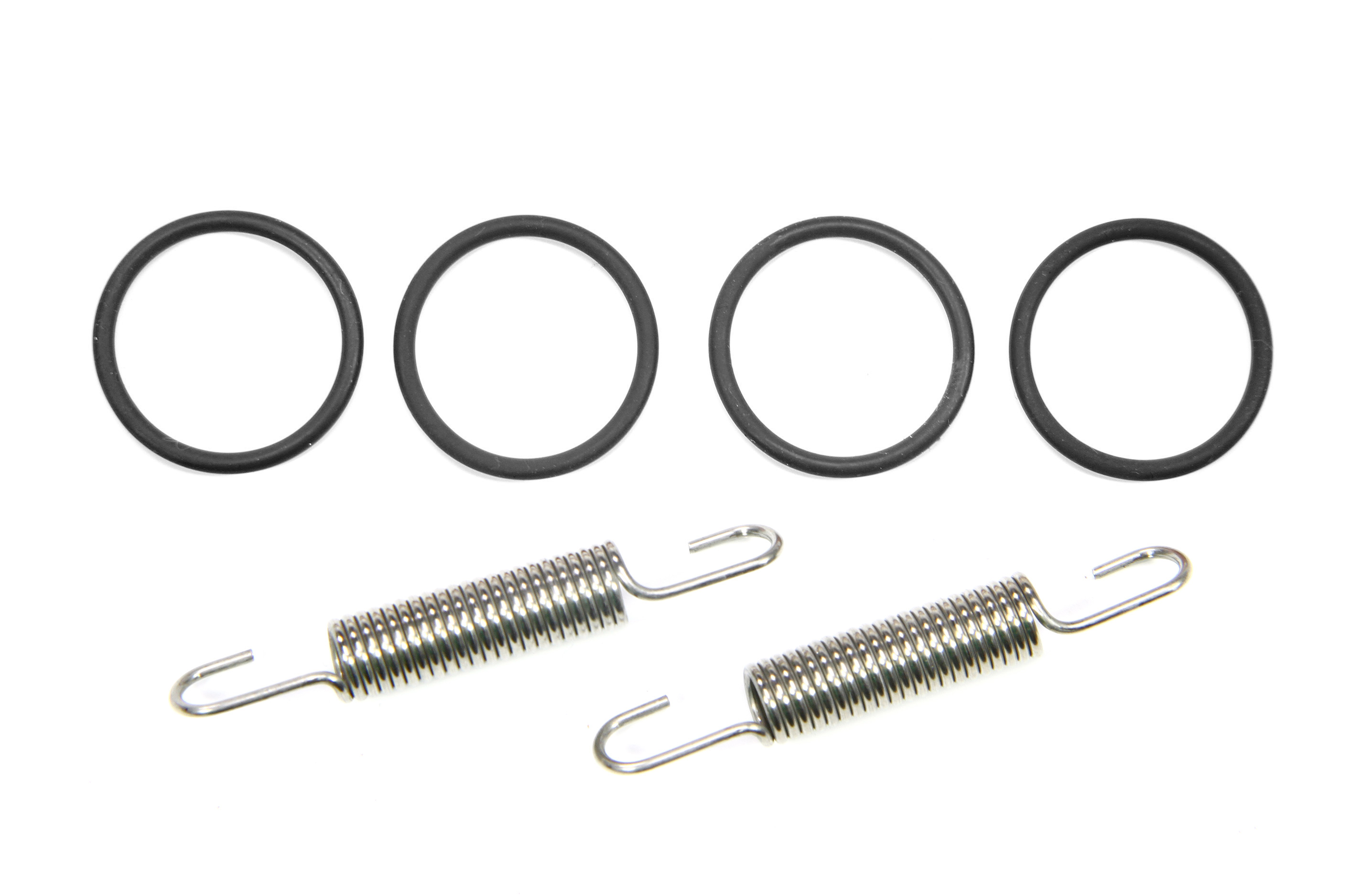

Genuine Samba spare/option part.Contents:2 x Replacement spring y03764 x O-ringe 20 x 24 x 2 mm